DCS50PD-2 Weigh Filler for Powder and Granule

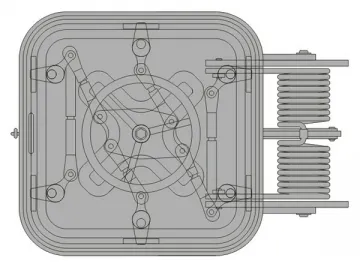

The DCS50PD-2 weigh filler for powder and granule involves utilization of variable frequency feeding instead of traditional feeding powered by double-speed electric motor. Therefore, customers benefit from stepless speed change, promoted feeling accuracy and intuitive digital setting.

Moreover, this semi-automatic packaging system is characterized by jam-preventing device and roller cage to guide conveyor belt and remove sticky materials. Furthermore, we adopt unique gating system for our weigh filling machine to minimize shock and vibration, resulting in drastically reduced noise.

This weigh filler is the tool of choice for free-flowing granules and powders with average flowing feature and stickiness, such as aquatic feed, gunk, livestock feed, wheat bran and rice bran, etc.

Specification| Production rate | 600 to 800 bags/h |

| Filling range | 20 to 50kg |

| Filling accuracy | × (0.2) level |

| Main motor power | 3500W |

| Air supply pressure | 0.6MPa |

| Applications | Free-flowing granules and powders with average flowing feature and stickiness, such as aquatic feed, gunk, livestock feed, wheat bran and rice bran, etc. |

| Features | 1. Frequency-controlled belt feeder 2. Dust-proof and environment-friendly drum scale 3. Two weighing hoppers to ensure precision and high speed |

Links:https://www.globefindpro.com/products/75934.html