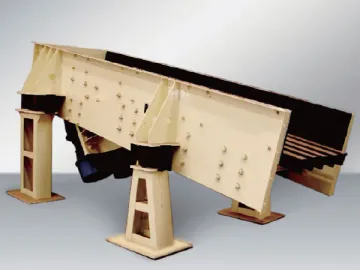

Vibrating Grizzly Feeder

The vibrating grizzly feeder is widely used for crushing and screening equipment in different industries such as metallurgy, coal, mineral processing, artificial sand, construction waste recycling, building materials, chemicals, abrasives, etc. As a high-efficiency vibrating feeding machine, this product is perfect for feeding while simultaneously prescreening fine powder. It is 65% to 70% cheaper than Metso, Sandvik and other international brands. Its performance is 95% to 98% of that of international brands.

Features

1. The vibrating grizzly feeder adopts the principle design of eccentric shaft vibration exciter. This ore crusher feeder is mainly used for feeding prior to coarse crushing.

2. Steady-state vibration avoids the phenomenon of failure. Also, it extends the service life of our feeding machine for mineral processing.

3. Feeding and prescreening fine powder simultaneously contributes to the improvement of crushing efficiency.

4. Adjustable grid bars prevent the blockage of material in the vibrating grizzly feeder.

5. A variable speed motor is optionally equipped to control the feed rate. There is no need to frequently start our motor vibratory feeder.

Performance Parameters

| Model | Maximum Feed Size (mm) | Speed (r/min) | Handling Capacity (t/h) | Power (kW) | Overall Dimension (mm) |

| ZSW380×95 | 500 | ~800 | 80 ~150 | 11 | 3970×2259×1880 |

| ZSW420×110 | 580 | ~800 | 120 ~240 | 15 | 4292×2519×2003 |

| ZSW490×110 | 580 | ~800 | 120 ~280 | 18.5 | 5093×2524×2014 |

| ZSW600×130 | 750 | ~800 | 140 ~450 | 30 | 6124×2863×2051 |

| ZSW600×150 | 600*900*1200 | 500 ~850 | 150 ~700 | 37 | 6271×2369×2698 |

| ZSW600×180 | 700*1050*1400 | 600 ~850 | 180 ~950 | 45 | 6375×2653×2913 |

Links:https://www.globefindpro.com/products/76057.html

-

Impact Crusher

Impact Crusher

-

NH, NS Series Hydraulic Cone Crusher

NH, NS Series Hydraulic Cone Crusher

-

Mobile Crusher and Screen

Mobile Crusher and Screen

-

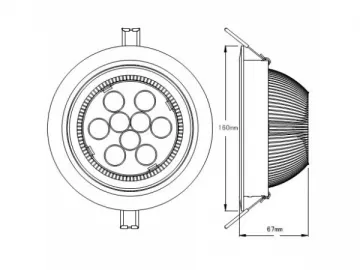

12W LED Ceiling Light

12W LED Ceiling Light

-

Universal Car Navigation System

Universal Car Navigation System

-

21W AR111 LED Spotlight

21W AR111 LED Spotlight

-

Stationary Crusher and Screen

Stationary Crusher and Screen

-

Audi TT Navigation System

Audi TT Navigation System

-

40W LED Ceiling Light

40W LED Ceiling Light

-

High Pressure Grinding Roll

High Pressure Grinding Roll

-

Audi A4 2003-2008 Navigation System

Audi A4 2003-2008 Navigation System

-

27W LED Ceiling Light

27W LED Ceiling Light