Vibrating Hopper

Introduction

Our GZG series vibrating hopper is our latest type arc-breaking feed hopper. It can serve as an excellent matiral feeding device when installed below the material storage silo. As a multifunctional hopper, its functions include arch destruction, stable feeding, flow stopping and flow adjusting. Various kinds of powdery and granular materials, even mixtures of materials with different granularity and specific gravity, in the hopper can be discharged stably and continuously.

Principle

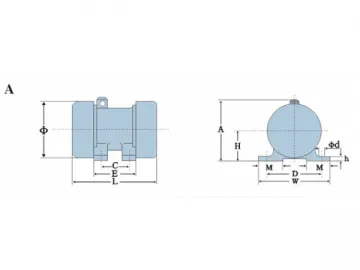

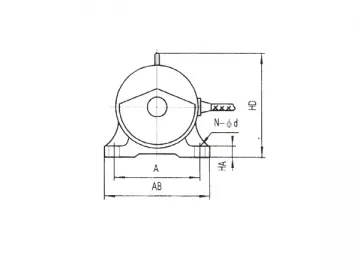

The GZG series vibrating hopper is composed of vibration motor, upper cylindrical wall, central vibrating cone, lower cone structure, sealing ring, and rubber spring. When the motor is rotating at a high speed, the two eccentric blocks at the both ends of the motor can generate exciting force, shaking the feeding hopper mounted upon the vibration absorbers continuously. Thus the central vibrating cone can keep loosening and discharging material in the hopper downward at a stable flow rate.

Feature

1. Our vibrating hopper has a round and compact structure and light weight. It can feed material stably and continuously.

2. The operation features low noise, low power consumption, and simple operation method.

3. The body is made of stainless steel or carbon steel, and the quick-wear parts are limited, so the machine’s service life is quite long.

4. The installation and maintenance are both quite simple.

5. The vibration motor of the vibrating hopper can be adjusted to achieve proper exciting force according to the requirements for feeding flow rate.

6. It perfectly matches various kinds of storage silos, no matter it is round or square, steel or concrete.

Application

This vibrating hopper can be widely used for industries like building material, chemical, metallurgy, machinery, ceramic, grain, food, glass, plastic, rubber, mining, medicine, and so on.

Product parameter

| Model | Feeding trough dimensions (L×W×H, mm) | Capacity(t/h) | Vibration motor | ||

| Model | Power (kW) | Speed (rpm) | |||

| GZG30-4 | 300 ×1000 ×160 | 15 | YZU2.5-4 | 0.18 ×2 | 1440 |

| GZG40-4 | 400 ×1200 ×160 | 30 | YZU5-4 | 0.25 ×2 | 1440 |

| GZG50-4 | 500 ×1200 ×160 | 60 | YZU8-4 | 0.55 ×2 | 1440 |

| GZG60-4 | 600 ×1500 ×180 | 100 | YZU10-4 | 0.55 ×2 | 1440 |

| GZG70-4 | 700 ×1500 ×200 | 130 | YZU15-4 | 0.75 ×2 | 1440 |

| GZG80-4 | 800 ×1600 ×230 | 180 | YZU20-4 | 1.1 ×2 | 1440 |

| GZG90-4 | 900 ×1600 ×230 | 240 | YZU20-4 | 1.1 ×2 | 1440 |

| GZG110-4 | 1100 ×1800 ×300 | 360 | YZU30-4 | 1.5 ×2 | 1440 |

| GZG130-4 | 1300 ×1800 ×300 | 480 | YZU30-4 | 1.5 ×2 | 1440 |

| GZG70-6 | 700 ×1500 ×200 | 150 | YZU10-6 | 0.75 ×2 | 960 |

| GZG80-6 | 800 ×1600 ×250 | 200 | YZU15-6 | 1.1 ×2 | 960 |

| GZG90-6 | 900 ×1600 ×250 | 260 | YZU20-6 | 1.5 ×2 | 960 |

| GZG110-6 | 1100 ×1800 ×300 | 380 | YZU30-6 | 2.2 ×2 | 960 |

| GZG130-6 | 1300 ×1800 ×300 | 500 | YZU30-6 | 2.2 ×2 | 960 |

| GZG150-6 | 1500 ×1800 ×300 | 500 | YZU40-6 | 3.0 ×2 | 960 |

Carbon feeding hopper

Stainless steel feeding hopper

Links:https://www.globefindpro.com/products/76099.html