Screw Conveyor

Introduction

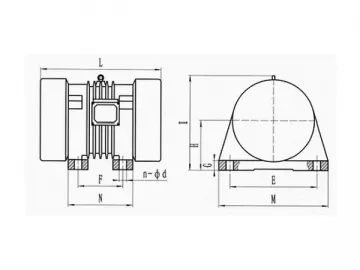

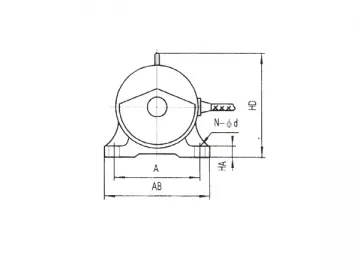

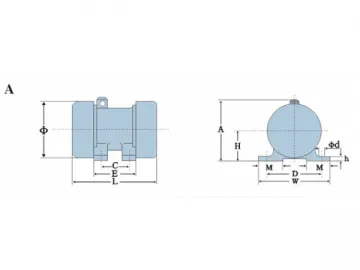

Our LS series screw conveyor adopts the Chinese equivalent standard of ISO1050-75. The hanger bearing comes with outside mounted grease cup, facilitating the replenishing of grease. The material inlet and outlet can be flexibly installed, while an electric outlet is optional for automatic control. Besides, a speed monitoring and alarming device could be added if you want.

Principle

The LS type screw conveyor comes with twelve diameter specifications ranging from 100mm to 1250mm. Two kinds of driving type, single drive and double drive, are available. The single drive type conveyor has a conveying distance of 40m, while the double drive type can convey for as far as 80m. Each section of the conveying equipment is 0.5m, so customizable the total conveying distance is according to your needs. The hanger bearings of this conveying machine come with two interchangeable structures, namely rolling type and sliding type. It bearing’s features include low frictional resistance, high sealing property, and great anti-wear performance.

Feature

1. This screw conveyor comes with reasonable structure, advanced technical parameters, great adaptability, and easy operation and repairing procedure.

2. This series of conveyor is available in ten types which can be divided into small size (LS100, LS125, LS160, LS200), medium size (LS250, LS315, LS400) and large size (LS500, LS630, LS800).

3. According to the materials to be conveyed, you can choose the right parameters from three filling coefficients and several rotating speed levels.

Application

This screw conveyor can be widely used in a number of industries like building material, metallurgy, chemical, electricity power, coal, and grain and food processing. To be specific, it can server as powder conveyor, granule conveyor, and small lump conveyor for materials like cement, coal powder, grain, fertilizer, sand, coal coke, and so on.

Product parameter

| Model | Screw diameter (mm) | Screw pitch (mm) | Rotary speed (r/min) | Max. conveying capacity (m3/h) | Motor power (kW) | Max. inclination angle ( ° ) |

| LS100 | 100 | 100 | 140 | 2.2 | 2.2---18.5 | ≤ 60 。 |

| LS125 | 125 | 125 | 125 | 4.0 | ||

| LS160 | 160 | 160 | 112 | 8 | ||

| LS200 | 200 | 200 | 100 | 11 | ||

| LS250 | 250 | 250 | 90 | 22 | ||

| LS315 | 315 | 315 | 80 | 34 | ||

| LS400 | 400 | 355 | 71 | 64 | ||

| LS500 | 500 | 400 | 63 | 95 | ||

| LS630 | 630 | 450 | 50 | 150 |

| Model | Head section/standard section (m) | End section (m) | ||||||||

| Small size | LS100~ LS200 | 2.5 | 1 | 1.5 | 2 | 2.5 | 3 | |||

| Medium size | LS250~ LS400 | 3 | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | ||

| Large size | LS500~ LS800 | 4 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 |

Product picture

Optional configuration and service

1. Different power voltages are supported, including 110V, 220V, 240V, 380V, 415V, 450V and 550V.

2. Both 50Hz and 60Hz power can be used for this screw conveyor.

3. The single-phase power adaptor and frequency converter are optional.

4. The OEM service is available.

Links:https://www.globefindpro.com/products/76110.html