Polypropylene Fiber

The polypropylene fiber, or geofiber, is meticulously manufactured from polypropylene, organic and inorganic materials through special production process, and it is mainly intended to reinforce the mechanical properties of concrete, thus extending the service life.

Function

Our structural polypropylene fiber forms a 3D random network in concrete so as to prevent micro crack growth at early ages of concrete setting, thereby enhancing the breaking strength, crack resistance and anti-permeability of concrete. So, this crack resistant fiber offers perfect resistance to crack, permeation, abrasion and heat for concrete and mortar projects.

1. Crack Resistance: The polypropylene fiber reduces non-structural cracks generated when concrete is in its plastic stage.

2. Anti-Permeability: Our synthetic concrete fiber is a rigid waterproof material that could avoid water permeation in concrete.

3. Dosage: 0.6-1.8kg/m3 (typical value: 0.9kg/m3)

| Monofilament Polypropylene Fiber | |||

| Raw material | Polypropylene | Elongation at break (%) | 20 |

| Type | Monofilament | Density (g/cm3) | 0.9 |

| Fiber diameter (mm) | (0.02-0.05)±0.005 | Melting point (℃) | 160-170 |

| Tensile strength (MPa) | 450 | Resistance to acid and alkali | Strong |

| Fiber length(mm) | 6, 10, 12, 15, 19, 20, etc. | Water absorbency | No |

| Polypropylene Fiber Tape | |||

| Density (g/cm3) | 0.91 | Elastic modulus (MPa) | >5000 |

| Length (mm) | 30, 40, 50 | Equivalent diameter (μm) | 80, 100 |

| Shape | Curved bar | Elongation at break (%) | ≤15±5 |

| Break strength (MPa) | ≥460 | Melting point (℃) | ≥160 |

Links:https://www.globefindpro.com/products/76233.html

-

Geomembrane

Geomembrane

-

Electric Fence Poly Wire

Electric Fence Poly Wire

-

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

-

Nylon Rope

Nylon Rope

-

E7018 Welding Electrode

E7018 Welding Electrode

-

EM12/EM12K Submerged Arc Welding Wire

EM12/EM12K Submerged Arc Welding Wire

-

Electric Fence Poly Tape

Electric Fence Poly Tape

-

ER70S-G High Strength Welding Wire

ER70S-G High Strength Welding Wire

-

E71T-1C Gas Shielded Mild Steel Flux Cored Wire

E71T-1C Gas Shielded Mild Steel Flux Cored Wire

-

E70T-4 Self Shielded Mild Steel Flux Cored Wire

E70T-4 Self Shielded Mild Steel Flux Cored Wire

-

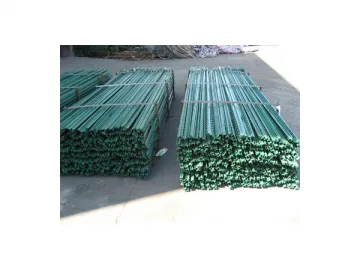

Steel Fence Post

Steel Fence Post

-

Electric Fence Poly Rope

Electric Fence Poly Rope