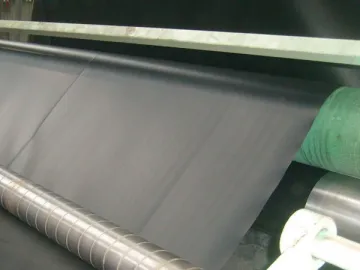

Geomembrane

Our geomembrane is meticulously crafted as per ASTM standards, and it is mainly made from polymer resin (high density polyethylene), thus imparting some outstanding properties to this synthetic flexible membrane, such as low permeability, good corrosion resistance, remarkable UV resistance, etc.

Application

Due to its superior features, our impermeable geomembrane liner offers efficient and cost-effective lining and covering solutions for reservoirs, mining factories, solid waste landfills, etc.

Water Storage Project

Solid Waste Landfill HDPEGeomembrane

Technical Data of Geomembrane

| Property | Test Method | Typical Value | ||||

| Thickness (mm) | ASTM D5199 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 |

| Density (g/cm3) | ASTMD792 | 0.94 | ||||

| Melting index (g/10min) | ASTM D1238 (190℃/2.16kg) | 1 | ||||

| Strength at break (kN/m) | ASTM D638 (at 50mm/min) | 14.5 | 30 | 40 | 54 | 69 |

| Elongation at break (%) | ASTM D638 (at 50mm/min) | 700 | 700 | 700 | 700 | 700 |

| Dimensional stability (%) | ASTM D1204 (100℃, 1hour) | ±2 | ||||

| Carbon black content (%) | ASTM D1603 | 2-3 | ||||

| Tear strength (N) | ASTM D1004 | 73 | 138 | 210 | 275 | 330 |

| Puncture strength (N) | ASTM D4833 | 159 | 316 | 475 | 636 | 793 |

| Oxygen induction time (min) | ASTM D3895 | 100 | ||||

| ESCR (hour) | ASTM D1693 | 1500 | ||||

| Absorption rate (%) | ASTM D570 (23℃) | 0.1 | ||||

| Water pressure resistance (MPa) | ASTM D751 | 1.0 | 2.2 | 3.1 | 4.1 | 5.2 |

| Thermal expansion coefficient (mm/℃) | ASTM D638 | 1.2×10-4 | ||||

| Landfilling test (% change) | ASTM D3083 | ±5 | ||||

Scan QR to Read

Links:https://www.globefindpro.com/products/76234.html

Links:https://www.globefindpro.com/products/76234.html

Recommended Products

-

Electric Fence Poly Wire

Electric Fence Poly Wire

-

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

-

Nylon Rope

Nylon Rope

-

E7018 Welding Electrode

E7018 Welding Electrode

-

EM12/EM12K Submerged Arc Welding Wire

EM12/EM12K Submerged Arc Welding Wire

-

Polyester Rope

Polyester Rope

-

Polypropylene Fiber

Polypropylene Fiber

-

Electric Fence Poly Tape

Electric Fence Poly Tape

-

ER70S-G High Strength Welding Wire

ER70S-G High Strength Welding Wire

-

E71T-1C Gas Shielded Mild Steel Flux Cored Wire

E71T-1C Gas Shielded Mild Steel Flux Cored Wire

-

E70T-4 Self Shielded Mild Steel Flux Cored Wire

E70T-4 Self Shielded Mild Steel Flux Cored Wire

-

Steel Fence Post

Steel Fence Post

Hot Products