E7018 Welding Electrode

The E7018 welding electrode comes with low hydrogen potassium coating. This welding accessory offers excellent wedalbility in all position welding for high strength steel and low alloy steel. Thanks to iron powder contained, our low alloy welding rod offers 11% welding efficiency.

Our welding electrode is characterized by remarkable impact toughness at low temperature and outstanding crack resistance. This high strength steel electrode excels at catering to demanding welds for ships, boilers, high-pressure vessels, bridges, high-rise buildings, offshore platforms and nuclear power plants, etc.

Standard

AWS E7018

Available size

2.5×300, 2.5×350, 3.2×350, 4.0×400, 4.0×450, 5.0×400, 5.0×450

| C | Mn | Si | S | P | Cr | Ni | Mo | V | |

| Standard | ≤0.15 | ≤1.60 | ≤.075 | ≤0.035 | ≤0.040 | ≤0.20 | ≤0.30 | ≤0.30 | ≤0.08 |

| Typical | 0.067 | 1.35 | 0.52 | 0.010 | 0.015 | 0.045 | 0.021 | 0.010 | 0.013 |

Mechanical properties of deposited metal

| ReH (Mpa) | Rm (Mpa) | A5 (%) | -20℃ | -29℃ | -46℃ | |

| Standard | ≥ 375 | 490-660 | ≥22 | ≥ 47 | ≥27 | ≥27 |

| Typical | 445 | 540 | 30 | 170 (J) | 150 (J) | 130 (J) |

Note

Surface of base metal should be cleaned up. Welding electrode requires 1-2 hour 400℃ preheat before welding. Welding rod in 2.5mm diameter only needs one hour preheat at 350℃ before welding.

Packaging

5kg/box, 4 boxes/carton

Each colorful box is wrapped with LDPE film and filled into carton.

Printing is based on customer's requirements.

Links:https://www.globefindpro.com/products/76238.html

-

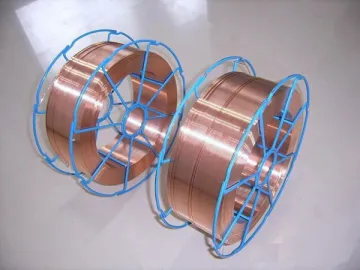

EM12/EM12K Submerged Arc Welding Wire

EM12/EM12K Submerged Arc Welding Wire

-

Polyester Rope

Polyester Rope

-

ER80S-G High Strength Welding Wire

ER80S-G High Strength Welding Wire

-

Zinc Wire

Zinc Wire

-

E309L-16 Welding Electrode

E309L-16 Welding Electrode

-

E70T-1C Gas Shielded Mild Steel Flux Cored Wire

E70T-1C Gas Shielded Mild Steel Flux Cored Wire

-

Nylon Rope

Nylon Rope

-

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

-

Electric Fence Poly Wire

Electric Fence Poly Wire

-

Geomembrane

Geomembrane

-

Polypropylene Fiber

Polypropylene Fiber

-

Electric Fence Poly Tape

Electric Fence Poly Tape