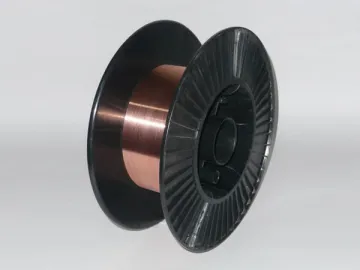

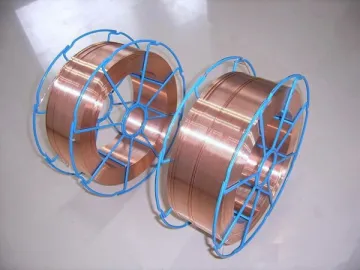

EL8/EL12 Submerged Arc Welding Wire

The EL8/EL12 submerged arc welding wire is the copper coated filler wire for carbon steel. This versatile welding consumable is well-suited for carbon steels and some low alloy steels applicable for industries of boilers, ships, pressure vessels and pipe, etc.

Our submerged arc welding wire is compatible with various kinds of fluxes, resulting in diversified wedability. Generally, this low alloy welding wire incorporating with fused flux is highly recommended for carbon steel requiring lower toughness, such as Q195 and Q215, etc. As for low alloy steels, such as 09Mn2, 16MnCu, 16Mn and 15MnTi, agglomerated flux is the preferred choice.

Standard

AWS EL8/EL12

GB/T: H08A

DIN: S1 BS: S1

Available diameter

2.0mm, 2.5mm, 3.2mm, 4.0mm, 5.0mm

Shielding gas

100% CO2 or 75%-95% Ar CO2 or 95% Ar CO2

Applicable flux

Fused flux: HJ431, HJ433 and HJ434, etc.

Agglomerated flux: SJ301, SJ302, SJ501, SJ502, SJ503 and SJ522, etc.

| C | Mn | Si | P | S | Cr | Ni | Cu | |

| Typical | 0.07 | 0.40 | 0.021 | 0.014 | 0.011 | 0.016 | 0.008 | 0.15 |

| Standard | ≤0.10 | 0.30-0.60 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.20 | ≤0.30 | ≤0.20 |

Note: Cu content in copper coated submerged arc welding wire should not be more than 0.35%.

Mechanical properties of deposited metal| Rm (MPa) | Rel (MPa) | A (%) | Akv (J) (-20℃) | |

| Typical | 485 | 372 | 29 | 60 |

| Standard | 415-550 | ≥330 | ≥22 | ≥27 |

Recommended welding data for carbon steel (DC )

| Wire diameter (mm) | Current (A) | Voltage (V) | Current type | Wire feed speed (m/h) | Interpasstemperature (℃) | Stick-out (mm) | |

| 1.6 | 350 | 30 ±2 | DC/AC | 18 | ±1.5 | 135-165 | 13-19 |

| 2.0 | 400 | 30 ±2 | DC/AC | 20 | ±1.5 | 135-165 | 13-19 |

| 2.5 | 450 | 30 ±2 | DC/AC | 21 | ±1.5 | 135-165 | 22-35 |

| 3.2 | 500 | 30 ±2 | DC/AC | 23 | ±1.5 | 135-165 | 22-35 |

| 4.0 | 550 | 30 ±2 | DC/AC | 25 | ±1.5 | 135-165 | 25-38 |

| 5.0 | 600 | 30 ±2 | DC/AC | 26 | ±1.5 | 135-165 | 25-38 |

| 6.0 | 650 | 30 ±2 | DC/AC | 27 | ±1.5 | 135-165 | 25-38 |

Note: If values of welding current or voltage exceed recommended range above, negative impacts will be led to mechanical properties and wedability of submerged arc welding wire.

Recommended welding data for low alloy steel (DC )

| Wire diameter (mm) | Current (A) | Voltage (V) | Current type | Wire feed speed (m/h) | Stick-out (mm) | Interpasstemperature (℃) | |

| 1.6 | 250-350 | 26-29 | DC/AC | 18 | ±1.5 | 13-19 | 150 ±15 |

| 2.0 | 300-400 | 26-29 | DC/AC | 18 | ±1.5 | 13-19 | 150 ±15 |

| 2.5 | 350-450 | 27-30 | DC/AC | 20 | ±1.5 | 19-32 | 150 ±15 |

| 3.0 | 400-500 | 27-30 | DC/AC | 23 | ±1.5 | 25-38 | 150 ±15 |

| 3.2 | 425-525 | 27-30 | DC/AC | 23 | ±1.5 | 25-38 | 150 ±15 |

| 4.0 | 475-575 | 27-30 | DC/AC | 25 | ±1.5 | 25-38 | 150 ±15 |

| 5.0 | 550-650 | 27-30 | DC/AC | 25 | ±1.5 | 25-38 | 150 ±15 |

| 6.0 | 625-725 | 28-31 | DC/AC | 29 | ±1.5 | 32-44 | 150 ±15 |

| 6.4 | 700-800 | 28-32 | DC/AC | 31 | ±1.5 | 38-50 | 150 ±15 |

Note: If values of welding current or voltage exceed recommended range above, negative impacts will be led to mechanical properties and wedability of submerged arc welding wire.

Packaging

1. 25kg-300kg/coil fine round package

2. 200kg and 300kg large iron or wood plate package

3. 25kg/spool in iron basket package

4. Other packages are upon request.

Links:https://www.globefindpro.com/products/76245.html

-

E312-16 Welding Electrode

E312-16 Welding Electrode

-

EH14 Submerged Arc Welding Wire

EH14 Submerged Arc Welding Wire

-

Gas Shielded Arc Welding Wire

Gas Shielded Arc Welding Wire

-

EM13K Submerged Arc Welding Wire

EM13K Submerged Arc Welding Wire

-

Geotextile

Geotextile

-

Geocell

Geocell

-

E70T-1C Gas Shielded Mild Steel Flux Cored Wire

E70T-1C Gas Shielded Mild Steel Flux Cored Wire

-

E309L-16 Welding Electrode

E309L-16 Welding Electrode

-

Zinc Wire

Zinc Wire

-

ER80S-G High Strength Welding Wire

ER80S-G High Strength Welding Wire

-

Polyester Rope

Polyester Rope

-

EM12/EM12K Submerged Arc Welding Wire

EM12/EM12K Submerged Arc Welding Wire