EH14 Submerged Arc Welding Wire

The EH14 submerged arc welding wire is a kind of solid welding wire. This welding consumable is compatible with various fluxes such as SJ101, HJ150, HJ330 and HJ350, resulting in prominent mechanical properties.

Our submerged arc welding wire is well-suited for welding of carbon steel and low alloy steel, such as 16Mn and 16MnCu. This carbon steel welding wire delivers impressive porosity resistance, slag detachability and high efficiency in multi-layer welding, double-sided welding, multi-wire welding and gap welding.

Standard

AWS A5.17 EH14 JIS: S501-H

GB/T: H10Mn2 DIN: S4 BS: S4

Available diameter

2.0mm, 2.5mm, 3.2mm, 4.0mm, 5.0mm

Shielding gas

100% CO2 or 75%-95% Ar CO2 or 95% Ar CO2

| C | Mn | Si | P | S | Ni | Cu | Cr | |

| Standard | ≤0.12 | 1.50-1.9 | ≤0.07 | ≤ 0.035 | ≤0.035 | ≤0.030 | ≤0. 20 | ≤0.20 |

| Typical | 0.07 | 1.85 | 0.021 | 0.015 | 0.017 | 0.016 | 0.014 | 0.021 |

Mechanical properties of deposited metal

| Re (MPa) | Rm (MPa) | A% | Charpy v-notch impact toughness | |||

| Test temp. (℃) | Impact energy (J) | Average (J) | ||||

| Standard | ≥ 420 | ≥410 | ≥ 22 | -20 | ≥34 | / |

| Typical | 460 | 570 | 29 | -20 | 85 | / |

Recommended welding data (DC )

| Wire diameter (mm) | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 |

| Current (A) | 300-400 | 350-450 | 425-525 | 475-575 | 550-650 |

Note

1. Submerged arc welding wire should be stocked in dry environment. Package opens only before welding to avoid corrosion.

2. Please clean up surface pollutions such as oil stains, rusts and water before welding.

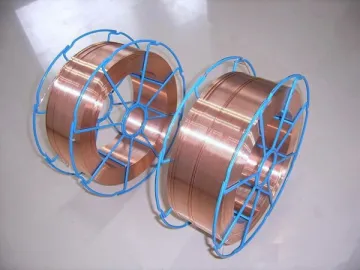

Packaging

1. 25kg-300kg/coil in fine round package

2. 200kg and 300kg large iron or wood plate package

3. 25kg/spool in iron basket package

4. Other packages are upon request.

Links:https://www.globefindpro.com/products/76247.html