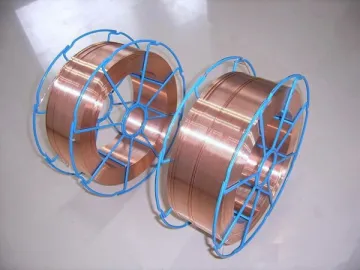

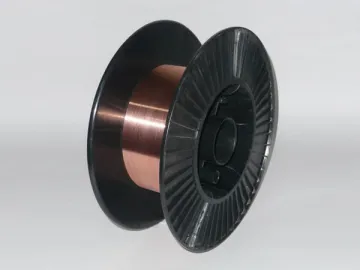

Gas Shielded Arc Welding Wire

The ER70S-6 gas shielded arc welding wire is designed for high-strength low-alloy steel (e.g. Q390, Q420 and Q460) with copper addition. This H08MnMoA welding wire incorporates with related flux to offer outstanding wedability, stable arc, and high slag detachability.

Our gas shielded arc welding wire generates flawless bead, offering prominent crack resistance and impact toughness at low temperature. This HSLA welding consumable is highly recommended for automobile, hoisting machinery, transport machinery, engineering machinery, shipbuilding, power plant, petrochemical engineering, bridge and pressure vessel, etc.

Standards

AWS A5.18 ER70S-6

AWS EL8/EL12

Available diameter

0.6mm, 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.4mm, 1.6mm

Compatible flux

1. Agglomerated flux: SJ101, SJ107, SJ301 and SJ501, etc.

2. Fused flux: HJ250, HJ350 and HJ431, etc.

| C | Mn | Si | P | S | Cr | Ni | Cu | Mo | Ti | |

| Typical | 0.08 | 1.34 | 0.14 | 0.015 | 0.013 | 0.021 | 0.011 | 0.14 | 0.38 | 0.06 |

| Standard | ≤ 0.10 | 1.20-1.60 | ≤ 0.25 | ≤ 0.030 | ≤ 0.030 | ≤ 0.20 | ≤ 0.30 | ≤ 0.20 | 0.30-0.50 | ≤ 0.15 |

Note: If gas shielded arc welding wire is copper coated, the copper content should be less than 0.35%.

Mechanical properties of deposited metal| Rm (MPa) | ReL (MPa) | A (%) | Akv (J) (-40℃) | |

| Typical | 618 | 495 | 25 | 101 |

| Standard | 550-700 | ≥ 470 | ≥ 20 | ≥ 27 |

Recommended welding data (DC , shielding gas: 100% CO2 or 75% Ar 25% CO2)

| Wire diameter (mm) | 0.6 | 0.8 | 0.9 | 1.0 | 1.2 | 1.4 | 1.6 |

| Current (A) | 30-100 | 60-200 | 70-250 | 80-300 | 120-380 | 150-420 | 225-550 |

| Voltage (V) | 15-20 | 18-24 | 18-26 | 18-32 | 18-34 | 22-36 | 28-35 |

Note: Procedures may vary in accordance with changes in position, base metals, filler material, equipment and other changes.

Recommended welding data for low alloy steel| Wire diameter(mm) | Current(A) | Voltage(V) | Current type | Wire feed speed (m/h) | Stick-out (mm) | Interpasstemperature (℃) | Postweldheat treatment (℃) | |

| 1.6 | 250-350 | 26-29 | DC/AC | 18 | ± 1.5 | 13-19 | 150 ± 15 | 620 ± 15 |

| 2.0 | 300-400 | 26-29 | DC/AC | 18 | ± 1.5 | 13-19 | 150 ± 15 | 620 ± 15 |

| 2.5 | 350-450 | 27-30 | DC/AC | 20 | ± 1.5 | 19-32 | 150 ± 15 | 620 ± 15 |

| 3.0 | 400-500 | 27-30 | DC/AC | 23 | ± 1.5 | 25-38 | 150 ± 15 | 620 ± 15 |

| 3.2 | 425-525 | 27-30 | DC/AC | 23 | ± 1.5 | 25-38 | 150 ± 15 | 620 ± 15 |

| 4.0 | 475-575 | 27-30 | DC/AC | 25 | ± 1.5 | 25-38 | 150 ± 15 | 620 ± 15 |

| 5.0 | 550-650 | 27-30 | DC/AC | 25 | ± 1.5 | 25-38 | 150 ± 15 | 620 ± 15 |

| 6.0 | 625-725 | 28-31 | DC/AC | 29 | ± 1.5 | 32-44 | 150 ± 15 | 620 ± 15 |

| 6.4 | 700-800 | 28-32 | DC/AC | 31 | ± 1.5 | 38-50 | 150 ± 15 | 620 ± 15 |

Note: If values of welding current or voltage exceed recommended range above, negative impacts will be led to mechanical properties and wedability of gas shielded arc welding wire. Other heat treatment regulations can be applied if necessary.

Packaging

15kg plastic spool, 72 cartons/pallet, 22 pallets/20' container

Links:https://www.globefindpro.com/products/76248.html

-

EM13K Submerged Arc Welding Wire

EM13K Submerged Arc Welding Wire

-

Geotextile

Geotextile

-

Geocell

Geocell

-

E310-16 Welding Electrode

E310-16 Welding Electrode

-

Hex Nuts

Hex Nuts

-

E71T-8 Self Shielded Mild Steel Flux Cored Wire

E71T-8 Self Shielded Mild Steel Flux Cored Wire

-

EH14 Submerged Arc Welding Wire

EH14 Submerged Arc Welding Wire

-

E312-16 Welding Electrode

E312-16 Welding Electrode

-

EL8/EL12 Submerged Arc Welding Wire

EL8/EL12 Submerged Arc Welding Wire

-

E70T-1C Gas Shielded Mild Steel Flux Cored Wire

E70T-1C Gas Shielded Mild Steel Flux Cored Wire

-

E309L-16 Welding Electrode

E309L-16 Welding Electrode

-

Zinc Wire

Zinc Wire