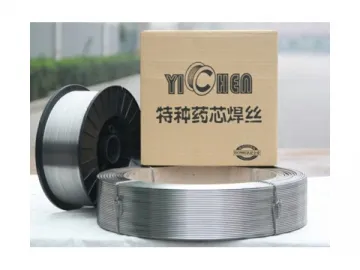

E81T1-B2C Low Alloy Steel Flux Cored Wire

The E81T1-B2C low alloy steel flux cored wire involves the utilization of Titanium slag system. Thisgas shielded welding wire is well-suited for 1%Cr-0.5%Mo heat resistant steel. Excellent weldability and stable arc can be achieved in all welding positions while offering low spatter, flawless bead appearance and superior slag detachability.

This kind of low alloy steel flux cored wire requires preheat process. The working temperature of this welding consumable is lower than 520℃. Therefore, our heat resistant steel flux cored wire is highly recommended for low alloy steel such as 15CrMo applicable for boiler, pressure vessel, oil tanker and oil refining equipment, etc.

Standards

GB/T 17493-2008 E551T1-B2C

AWS A5.29 E81T1-B2C

Chemical composition of deposited metal (%)

| C | Mn | Si | P | S | Cr | Mo | |

| Standard | 0.05-0.12 | ≤1.25 | ≤0.80 | ≤0.03 | ≤0.03 | 1.00-1.50 | 0.40-0.65 |

| Typical | 0.06 | 0.79 | 0.19 | 0.011 | 0.008 | 1.20 | 0.45 |

Mechanical properties of deposited metal (620℃ × 1h)

| Rm (MPa) | Rp0.2 (MPa) | A5 (%) | |

| Standard | 550-690 | ≥470 | ≥19 |

| Typical | 630 | 560 | 22 |

Recommended welding data (DC , shielding gas: CO2)

| Wire diameter (mm) | Current (A) | Voltage (V) | Gas (l/min) |

| Φ1.2 | 200-280 | 24-30 | 15-20 |

| Φ1.6 | 220-300 | 24-32 | 15-20 |

Scan QR to Read

Links:https://www.globefindpro.com/products/76258.html

Links:https://www.globefindpro.com/products/76258.html

Recommended Products

-

YC-YD255(Q) Gas Shielded Hardfacing Flux Cored Wire

YC-YD255(Q) Gas Shielded Hardfacing Flux Cored Wire

-

YC-YD256(Q) Gas Shielded Hardfacing Flux Cored Wire

YC-YD256(Q) Gas Shielded Hardfacing Flux Cored Wire

-

E81T1-W2C Low Alloy Steel Flux Cored Wire

E81T1-W2C Low Alloy Steel Flux Cored Wire

-

E309LT0-1/4 Stainless Steel Flux Cored Wire

E309LT0-1/4 Stainless Steel Flux Cored Wire

-

YC-YD558(Q) Gas Shielded Hardfacing Flux Cored Wire

YC-YD558(Q) Gas Shielded Hardfacing Flux Cored Wire

-

YC-YD107(Q) Gas Shielded Hardfacing Flux Cored Wire

YC-YD107(Q) Gas Shielded Hardfacing Flux Cored Wire

-

YC-ZG100(Q) Gas Shielded Hardfacing Flux Cored Wire

YC-ZG100(Q) Gas Shielded Hardfacing Flux Cored Wire

-

Polypropylene Rope

Polypropylene Rope

-

E71T-1JC/9JC Gas Shielded Mild Steel Flux Cored Wire

E71T-1JC/9JC Gas Shielded Mild Steel Flux Cored Wire

-

E71T-8 Self Shielded Mild Steel Flux Cored Wire

E71T-8 Self Shielded Mild Steel Flux Cored Wire

-

Hex Nuts

Hex Nuts

-

E310-16 Welding Electrode

E310-16 Welding Electrode

Hot Products