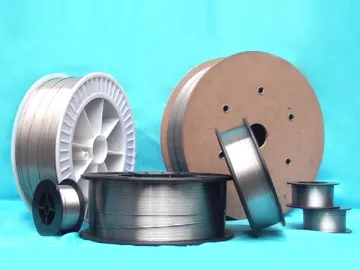

E81T1-Ni1C Low Alloy Steel Flux Cored Wire

The E81T1-Ni1C low alloy steel flux cored wire comes with Titanium slag system.This CO2 welding wire generates flawless bead appearance, low spatter, excellent slag detachability and porosity resistance.

Moreover, this kind of low alloy steel flux cored wire is capable of showing exceptional impact toughness and considerable mechanical properties even in low temperature. Therefore, this heat resistant steel welding consumable has been extensively applied to all position welding for shipbuilding, offshore structures, bridges and storage tanks, etc.

Standards

GB/T17493-2008 E5511T1-Ni1C

AWS A5.29 E81T1-Ni1C

Chemical composition of deposited metal (%)

| C | Mn | Si | Ni | S | P | |

| Standard | ≤0.12 | ≤1.50 | ≤0.80 | 0.80-1.10 | ≤0.03 | ≤0.03 |

| Typical | 0.06 | 1.25 | 0.42 | 0.96 | 0.015 | 0.018 |

Mechanical properties of deposited metal

| Rm (MPa) | Rp0.2 (MPa) | A5 (%) | Akv (J) (-30℃) | Akv (J) (-40℃) | |

| Standard | 550-690 | ≥470 | ≥19 | ≥27 | ≥27 |

| Typical | 640 | 540 | 24 | 110 | 86 |

Recommended welding data (DC , shielding gas: CO2)

| Wire diameter (mm) | Current (A) | Voltage (V) | Gas (l/min) |

| Φ1.2 | 180-300 | 24-30 | 15-25 |

| Φ1.6 | 200-300 | 24-32 | 15-25 |

Scan QR to Read

Links:https://www.globefindpro.com/products/76314.html

Links:https://www.globefindpro.com/products/76314.html

Recommended Products

-

DVR Touch Screen Alarm System

DVR Touch Screen Alarm System

-

X2 GSM GPRS Alarm System

X2 GSM GPRS Alarm System

-

E100T5-K3C Low Alloy Steel Flux Cored Wire

E100T5-K3C Low Alloy Steel Flux Cored Wire

-

Injection Mould for Traffic Light Lens

Injection Mould for Traffic Light Lens

-

186P Home IP Camera

186P Home IP Camera

-

X1 GSM GPRS Alarm System

X1 GSM GPRS Alarm System

-

G50B GSM Alarm System

G50B GSM Alarm System

-

137P Home IP Camera

137P Home IP Camera

-

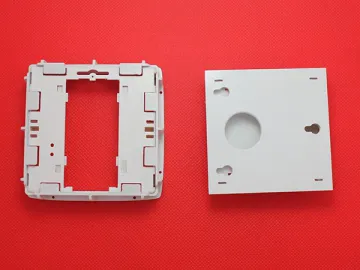

Injection Mold for Housing

Injection Mold for Housing

-

Rapid Prototyping for Plastic Parts

Rapid Prototyping for Plastic Parts

-

G10 GSM Alarm System

G10 GSM Alarm System

-

Customized Disposable Container

Customized Disposable Container