GZH Volumetric Filling Machine

Model GZH semi-automatic volumetric filling machine provides big filling performance in only a small footprint. It is a positive displacement filler that comes equipped with quality pneumatic components. Its drive pressure ranges from 0.1MPa to 0.4MPa.

High filling accuracy and operational stability are the major benefits of this volumetric filling machine. Product contact parts are made of SUS316L stainless steel to meet related GMP requirements. The volumetric filler has become a preferred choice when it comes to filling medium-viscosity pastes, honey, and liquid cosmetics. Therefore, if you are looking for liquid filling machines or paste filling machines, please don't hesitate to contact us.

Main Parts

Model GZH volumetric filling machine is made up of the hopper, filling head, air-operated switch for return stroke, air –operated switch for filling stroke, fill volume adjustment handle, air cylinder, and the foot switch.

Working Principle

The piston moves up and down in a straight line inside the cylinder. This mechanical energy is then used to suck up and fill the material.

Features

1. This volumetric filling machine relies on a positive displacement pump for accurate filling.

2. All the moving parts are operated by pressurized air. The filling equipment is especially suitable for use in potential explosive environment.

3. The whole filling process does not produce any static electricity that might cause uncomfortable tingling feeling. The filler does not need grounding.

Technical Specifications

| Specification | B40 | B60 | B80 | B100 |

| Hopper Volume ( L ) | 45 | 45 | 45 | 45 |

| Filing Volume ( ml ) | 15-150 | 50-300 | 100-500 | 200-1000 |

| Yield (Time/min) | 40-100 | 35-80 | 25-60 | 15-40 |

| Cylinder Diameter (mm) | 40 | 60 | 80 | 100 |

| Drive Power (MPa) | 0.1-0.4 | |||

| Dimension(mm) | 500 × 500 × 1600 | |||

| Weight(kg) | 55-65 | |||

Links:https://www.globefindpro.com/products/76444.html

-

Water Purification System

Water Purification System

-

Helical Worm Gearbox

Helical Worm Gearbox

-

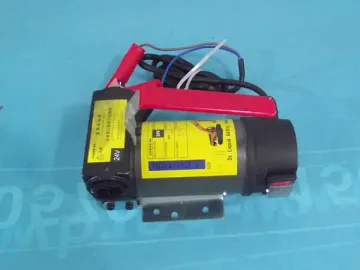

DC Refuelling Pump

DC Refuelling Pump

-

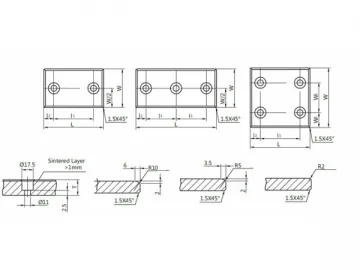

#50HP Solid Lubricated Copper Bearing

#50HP Solid Lubricated Copper Bearing

-

DNB-#200P20 20mm Thick Wear Plate

DNB-#200P20 20mm Thick Wear Plate

-

DNB-#200B Oilless Self-lubricating Bushes

DNB-#200B Oilless Self-lubricating Bushes

-

NMRV Worm Gearbox

NMRV Worm Gearbox

-

KRHA Vacuum Mixer Homogenizer

KRHA Vacuum Mixer Homogenizer

-

5L Jerry Can with Bayonet Closure

5L Jerry Can with Bayonet Closure

-

20L Aluminum Jerry Can

20L Aluminum Jerry Can

-

10L Horizontal Metal Jerry Can

10L Horizontal Metal Jerry Can

-

20L Square Metal Jerry Can

20L Square Metal Jerry Can