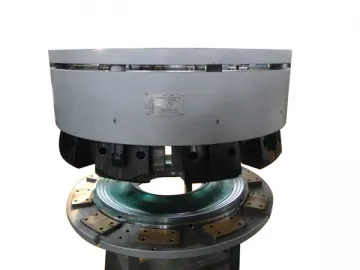

RH II Vacuum Mixer Homogenizer

It makes quality sense for producers of mid and high-class oil-in-water or powdery cosmetics to pick this RHII vacuum mixer homogenizer. Available with the external circulation tubing that is attached to the bottom homogenizer, this cosmtic manufacturing equipment enables a thorough, intense mixing. It serves as a guarantee that the resulting cosmetics meet quality specifications.

As a popular selection of high shear batch mixer, the vacuum mixer homogenizer is available in 6 different models with main tank volumes ranging from 200L to 1000L to suit different scales of production.

Main Parts

Model RHII vacuum mixer homogenizer is made up of the main emulsification tank (with tank lid that can rise and lower, external circulation piping), high-shear homogenizer (at the bottom), oil-in-water dissolving tank, vacuum suction device, heating and cooling system, and the electrical enclosure.

Features of the Vacuum Mixer Homogenizer

1. Materials are mixed intensely and circulated back to repeat the mixing cycle via the external circulation piping that connects between the main emulsification tank and the bottom homogenizer. Inside the rotor-stator homogenizer, the material is subjected to high shear rate to ensure a more through mixing. The piping also can be used to discharge the finished mixture.

2. The cosmetic homogenizer is a fully enclosed structure, available with a cooling system. It is able to operate continuously for a long time without getting overheated.

3. Vacuum suction method reduces the number of bubbles contained in the mixture, ensuring fine, flexible emulsions.

4. Product contact parts are made of SUS316L stainless steel through polishing and passivation. Food grade high shear mixer ensures process hygiene.

5. Available in volume from 200L to 1000L, our vacuum mixer homogenizer can be tailored to your specific requirements.

Technical Specifications of the Vacuum Mixer Homogenizer

| Type | Working Volume | Full Volume of Dissolving Tank (Premix Tank) | Block Dimension | Total Power | Weight |

| L | L | L×W×H mm | KW | Kg | |

| 200 | 200 | 129/188 | 3100×3000×2500~3450 | 14.5 | 2450 |

| 300 | 300 | 188/314 | 3600×3350×2650~3600 | 14.5 | 2850 |

| 500 | 500 | 250/500 | 4350×3600×2750~4000 | 22.4 | 3500 |

| 600 | 600 | 380/500 | 4500×3600×2900~4250 | 22.4 | 3900 |

| 800 | 800 | 500/1030 | 4900×3800×3100~4500 | 31 | 4800 |

| 1000 | 1000 | 600/1030 | 5400×4000×3300~4750 | 31 | 7000 |

Links:https://www.globefindpro.com/products/76456.html

-

ZG Industrial Mixer(For Paste Making)

ZG Industrial Mixer(For Paste Making)

-

Vacuum Storage Tank

Vacuum Storage Tank

-

Tie Bar Bushes

Tie Bar Bushes

-

Guide Element for Auto Body Press Die

Guide Element for Auto Body Press Die

-

#50SP5-SL1 Solid Lubricated Brass Bearing

#50SP5-SL1 Solid Lubricated Brass Bearing

-

XP Industrial Mixer(For Perfume Making)

XP Industrial Mixer(For Perfume Making)

-

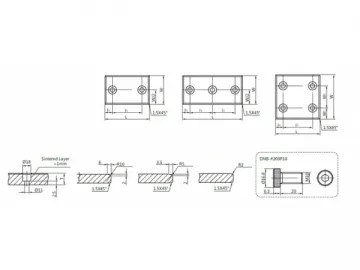

DNB-#200P10 10mm Thick Wear Plate

DNB-#200P10 10mm Thick Wear Plate

-

Self-Lubricating Plate for Radial Tire Mould

Self-Lubricating Plate for Radial Tire Mould

-

MP10 Composite Bearing (Steel Backed PTFE Coated Bronze)

MP10 Composite Bearing (Steel Backed PTFE Coated Bronze)

-

ZYX Industrial Mixer(For Lotion Making)

ZYX Industrial Mixer(For Lotion Making)

-

DNB-#200B Oilless Self-lubricating Bushes

DNB-#200B Oilless Self-lubricating Bushes

-

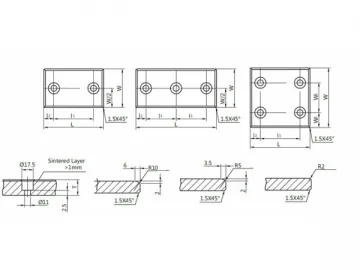

DNB-#200P20 20mm Thick Wear Plate

DNB-#200P20 20mm Thick Wear Plate