YX Industrial Mixer(For Shampoo Making)

Clean, durable, and carefree, it's no wonder that the stainless steel is the most popular choice when it comes to the industrial mixer for shampoo making. The contact parts of our shampoo mixer are made of SUS316L stainless steel, which delivers a high level of corrosion resistance and a long time of service. The whole vacuum mixing machine is supported by 3 cylindrical posts at the bottom. This stabilized structure makes sure that the mixing tank is unlikely to overturn.

In addition to shampoo making, the industrial mixer also has a critical part to play in other cosmetic or pharmaceutical mixing process. Its mixing configurations can be customized to fit specific production processes.

Main Parts of the Industrial Mixer

The industrial mixing equipment is made up of the stainless steel mixing tank (with a flat lid), heating and cooling system, electrical enclosure, and support feet.

Working Principle

Inside the tank, various heated materials are subjected to the combined mixing actions of the bottom anchor impeller and top straight-blade impeller. The industrial mixer is designed with flow-directing baffles along the tank wall, which help make sure the materials can be mixed thoroughly.

Features of the Industrial Mixer

1. Various types of impellers are available to suit your actual mixing requirements.

2. This industrial vacuum mixer comes with a frequency converter to deliver different mixing speeds, which allow the materials to be tumbled and mixed properly.

3. The surface of our industrial agitator has been polished and passivated to obtain a clean, corrosion-resistant finish. Food grade tank mixer ensures the hygiene of the shampoo mixing process.

Technical Specifications of the Industrial Mixer

| Type | Working Volume | Mixing Power | Dimension |

| L | kw | L×W×H mm | |

| 500L | 500 | 2.2 | 2200×1400×2500 |

| 1000L | 1000 | 3 | 2500×1700×2700 |

| 2000L | 2000 | 4 | 2750×1940×3100 |

| 3000L | 3000 | 4 | 3000×2150×3500 |

| 5000L | 5000 | 5.5 | 3200×2400×3950 |

Links:https://www.globefindpro.com/products/76467.html

-

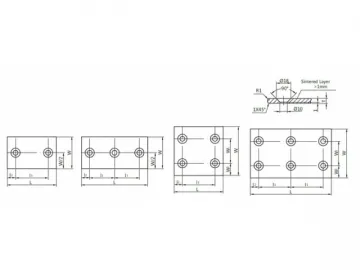

Self-Lubricating Plate for Tire Mould

Self-Lubricating Plate for Tire Mould

-

#50AB-SL1 Solid Lubricated Aluminum Bronze Bearing

#50AB-SL1 Solid Lubricated Aluminum Bronze Bearing

-

KRH Vacuum Mixer Homogenizer

KRH Vacuum Mixer Homogenizer

-

Thermoplastic Bushes

Thermoplastic Bushes

-

RH Vacuum Mixer Homogenizer

RH Vacuum Mixer Homogenizer

-

GX Planetary Mixer

GX Planetary Mixer

-

DNB-#200P5 5mm Thick Wear Plate

DNB-#200P5 5mm Thick Wear Plate

-

Toggle Bushes

Toggle Bushes

-

#50B Solid Lubricated Bronze Bearing

#50B Solid Lubricated Bronze Bearing

-

MP20 Composite Bearing (Steel Backed POM/PEEK Coated Bronze)

MP20 Composite Bearing (Steel Backed POM/PEEK Coated Bronze)

-

XP Industrial Mixer(For Perfume Making)

XP Industrial Mixer(For Perfume Making)

-

#50SP5-SL1 Solid Lubricated Brass Bearing

#50SP5-SL1 Solid Lubricated Brass Bearing