KRH Vacuum Mixer Homogenizer

This selection of vacuum mixer homogenizer is available with an interesting feature that would make material discharge and tank maintenance and repair easier than before. The inclinable mixing tank comes with a movable lid that is able to vertically raise or lower its position.

Primarily fabricated from stainless steel, the KRH vacuum mixer homogenizer represents an enhanced version over the RH series vacuum homogenizers. It can be used for producing low and mid-class cosmetic and pharmaceutical products such as ointments and lotions. The whole emulsification process is operated under hermetic conditions to keep out any dust or microorganisms. Its resulting emulsion always looks fine and glossy.

Note

If you intend to use our emulsifier machine for pharmaceutical applications, please let us know. We can customize the vacuum mixer homogenizer to food-grade quality standards.

Main Parts

Model KRH vacuum mixer homogenizer is made up of the main emulsification tank(with movable lid and tiltable tank body), bottom-mounted rotor-stator homogenizer, dissolving pot, vacuum suction device, heating and cooling system, and the electrical enclosure.

Features of the Vacuum Mixer Homogenizer

1. Vacuum suction method reduces the number of bubbles included in the finished mixture, which in turn ensures fine, flexible emulsions.

2. Product contact parts are made of SUS316L stainless steel through polishing and passivation processes. Food-grade vacuum mixer ensures process hygiene.

Technical Specifications of the Vacuum Mixer Homogenizer

| Type | Working Volume | Full Volume of Dissolving Pot (Premix Tank) | Block Dimension | Total Power | Weight |

| L | L | L×W×H mm | KW | Kg | |

| 50 | 50 | 50/80 | 2450×2300×1980~2680 | 7 | 950 |

| 100 | 100 | 96/129 | 2900×2650×2150~3020 | 8.6 | 2000 |

| 150 | 150 | 96/160 | 3000×2650×2200~3100 | 9.6 | 2200 |

| 200 | 200 | 129/188 | 3100×2740×2250~3260 | 11 | 2450 |

| 300 | 300 | 188/314 | 3260×2900×2400~3500 | 13.4 | 2850 |

| 500 | 500 | 250/500 | 3600×3270×2750~4000 | 16.7 | 3500 |

| 600 | 600 | 380/500 | 3700×3370×2900~4250 | 16.9 | 3800 |

| 800 | 800 | 500/1030 | 4100×3450×3100~4500 | 24.4 | 4800 |

| 1000 | 1000 | 600/1030 | 4200×3600×3300~4800 | 24.4 | 6000 |

Links:https://www.globefindpro.com/products/76470.html

-

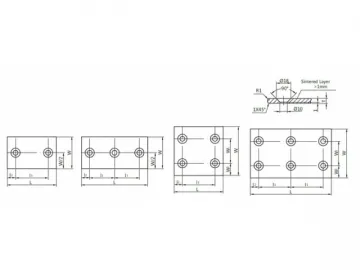

Thermoplastic Bushes

Thermoplastic Bushes

-

RH Vacuum Mixer Homogenizer

RH Vacuum Mixer Homogenizer

-

GX Planetary Mixer

GX Planetary Mixer

-

XRH Lab Homogenizer

XRH Lab Homogenizer

-

Plastic Mold Bushes

Plastic Mold Bushes

-

#50SP1-SL1 Solid Lubricated Brass Bearing

#50SP1-SL1 Solid Lubricated Brass Bearing

-

#50AB-SL1 Solid Lubricated Aluminum Bronze Bearing

#50AB-SL1 Solid Lubricated Aluminum Bronze Bearing

-

Self-Lubricating Plate for Tire Mould

Self-Lubricating Plate for Tire Mould

-

YX Industrial Mixer(For Shampoo Making)

YX Industrial Mixer(For Shampoo Making)

-

DNB-#200P5 5mm Thick Wear Plate

DNB-#200P5 5mm Thick Wear Plate

-

Toggle Bushes

Toggle Bushes

-

#50B Solid Lubricated Bronze Bearing

#50B Solid Lubricated Bronze Bearing