RH Vacuum Mixer Homogenizer

Model RH vacuum mixer homogenizer comes with a fixed rotor-stator homogenizer at its bottom. The unique selling points of this industrial-scale emulsifying mixer are its simplified structure and adjustable mixing speed. At either a 1400r/min or 2800r/min rate, the high shear mixer runs rather quietly while creating good mixing effects.

Depending on the size of production runs in your company, we offer 10 types of vacuum mixer homogenizers with volumes in the range from 100L to 3000L. Though this high shear batch mixer is most commonly found in small and medium-sized equipment, it can be customized to suit large-scale production requirements.

Main Components

This cosmetic manufacturing equipment is comprised of the main emulsification tank (with a fixed lid), high-shear homogenizer (at the bottom), dissolving tank (premix tank), vacuum suction device, heating and cooling system, and the electrical enclosure.

Features

1. The vacuum mixer homogenizer is inclined at an angle of 150° to the centerline of the emulsifying mixer tank. This arrangement allows the material to tumble naturally, eliminating any "catch points" that would trap liquids. Therefore, all the materials can get mixed uniformly.

2. Vacuum suction method is adopted during mixing to reduce the number of bubbles found in the mixture. The resulting emulsion can have a shiny, fine, and flexible texture.

Technical Specifications of the Vacuum Mixer Homogenizer

| Type | Working Volume | Full Volume of Dissolving Tank | Dimension | Total Power | Weight |

| L | L | L×W×H mm | Kw | Kg | |

| 100 | 100 | 96/129 | 2650×2350×2520 | 7.1 | 1500 |

| 150 | 150 | 96/160 | 2700×2650×2580 | 8.1 | 1700 |

| 200 | 200 | 129/188 | 2750×2740×2600 | 8.8 | 1950 |

| 300 | 300 | 188/314 | 3060×2900×2750 | 11 | 2150 |

| 500 | 500 | 250/500 | 3380×3270×3200 | 14.5 | 3000 |

| 600 | 600 | 380/500 | 3480×3370×3300 | 14.5 | 3400 |

| 800 | 800 | 470/710 | 3750×3600×3450 | 21 | 4200 |

| 1000 | 1000 | 637/1030 | 3800×3700×3580 | 21 | 5000 |

| 2000 | 2000 | 1000/1900 | 4500×4250×4000 | 27.7 | 8500 |

| 3000 | 3000 | 1400/2200 | 6800×5100×5030 | 35 | 11500 |

| 5000 | 5000 | 2400/3200 | 7800×6500×6050 | 40.5 | 15300 |

Links:https://www.globefindpro.com/products/76472.html

-

GX Planetary Mixer

GX Planetary Mixer

-

XRH Lab Homogenizer

XRH Lab Homogenizer

-

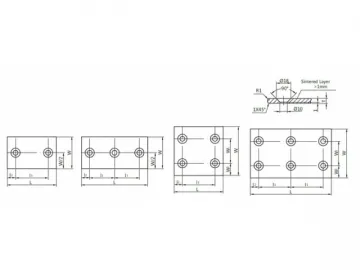

Plastic Mold Bushes

Plastic Mold Bushes

-

#50SP1-SL1 Solid Lubricated Brass Bearing

#50SP1-SL1 Solid Lubricated Brass Bearing

-

#50SP1-SL4 Water Lubricated Brass Bearing

#50SP1-SL4 Water Lubricated Brass Bearing

-

Modular Belt Conveyor

Modular Belt Conveyor

-

Thermoplastic Bushes

Thermoplastic Bushes

-

KRH Vacuum Mixer Homogenizer

KRH Vacuum Mixer Homogenizer

-

#50AB-SL1 Solid Lubricated Aluminum Bronze Bearing

#50AB-SL1 Solid Lubricated Aluminum Bronze Bearing

-

Self-Lubricating Plate for Tire Mould

Self-Lubricating Plate for Tire Mould

-

YX Industrial Mixer(For Shampoo Making)

YX Industrial Mixer(For Shampoo Making)

-

DNB-#200P5 5mm Thick Wear Plate

DNB-#200P5 5mm Thick Wear Plate