Parallel Slide Gate Valve

Parallel Slide Gate Valve

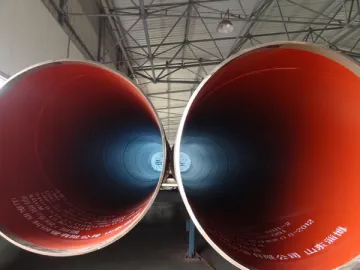

The parallel slide gate valve can be designed with single disc or double disc. This product is widely employed for flow control of water, steam, oil, natural gas and other corrosive mediums.

Features

1. Produced with parallel structure, the flanged parallel slide gate valve has high machining precision.

2. The disc slides on the surface of the valve seat. The automatic positioning of the sealing surface will not be affected by the thermal deformation of the valve body.

3. The high pressure of the inner cavity can be released automatically when the parallel slide gate valve is closed, ensuring the safety in use.

4. According to customer’s requirement, the welded parallel slide gate valve can be manufactured with guiding holes. Installed on the pipeline, the product can be cleaned with tube cleaner directly.

Technical Parameters

Design and Manufacturing Standard | ANSI/ASME B16.34 |

Standard of Structure Length | ANSI/ASME B16.10 |

Flange Connection Standard | ANSI/ASME B16.5 for NPS≤24" |

Weld Standard | ANSI/ASME B16.25 |

Norminal Diameter | 2"-12" |

Pressure | Class 150-Class 900 |

Material of Valve Body | WCB(A105), WC6, WC9, LCB, CF8(304), CF8M(316), CF3(304L), CF3M(316L), etc. |

Material of Sealing Surface | Rubber, teflon, cemented carbide, etc. |

Connection Type | Flange, weld |

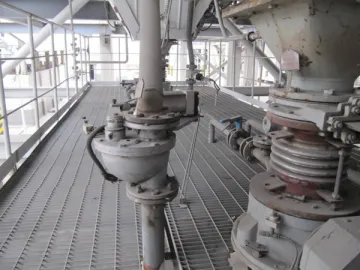

Drive Mode | Manual drive, electric drive, pneumatic drive |

Applicable Medium for Pneumatic Parallel Slide Gate Valve

The parallel slide gate valve can be used by the pipeline for the medium like water, steam, oils, liquefied gas, natural gas, coal gas, hydrogen nitrate, acetic acid, urea, oxidant, and some others.

(,PDF(),pdf,:http://cn-changlin.com/wheel-loader-937h.html)

Title: Parallel Slide Gate ValveQUANSHUN

Keywords: Parallel slide gate valve, welded parallel slide gate valve, flanged parallel slide gate valve, fluid control device, gate valve

Description: The parallel slide gate valve can be designed with single disc or double disc. The high pressure inside the inner cavity can be released automatically when the product is closed, guaranteeing safety in use.

Translation:

Parallel Slide GateValve

The parallel slide gate valve comes with either a single disc or double disc.This product is widely employed for the flow control of water, steam, oil,natural gas, and corrosive mediums.

Features

1. Produced with a parallel structure, the flanged parallel slide gate valve has high machiningprecision.

2. The disc slides on the surface of the valve seat. The automatic positioningof the sealing surface will not be affected by the thermal deformation of thevalve body.

3. The high pressure of the inner cavity can be released automatically when theparallel slide gate valve is closed as a safety feature.

4. According to customer requirements,the welded parallel slide gate valve can be manufactured with guiding holesinstalled on the pipeline. The product can be cleaned with tube cleanerdirectly.

Technical Parameters

Design and Manufacturing Standard

ANSI/ASME B16.34

Standard of Structure Length

ANSI/ASME B16.10

Flange Connection Standard

ANSI/ASME B16.5 for NPS≤24"

Weld Standard

ANSI/ASME B16.25

Nominal Diameter

2"-12"

Pressure

Class 150-Class 900

Material of Valve Body

WCB(A105), WC6, WC9, LCB, CF8(304), CF8M(316), CF3(304L), CF3M(316L), etc.

Material of Sealing Surface

Rubber, teflon, cemented carbide, etc.

Connection Type

Flange, weld

Drive Mode

Manual drive, electric drive, pneumatic drive

ApplicableMedium for Pneumatic Parallel Slide Gate Valve

The parallel slide gate valve can be used by the pipeline for themediums such as water, steam, oils, liquefied gas, natural gas, coal gas,hydrogen nitrate, acetic acid, urea, and oxidants.

(,PDF(),pdf,:http://cn-changlin.com/wheel-loader-937h.html)

Title: Parallel Slide Gate Valve︱QUANSHUN

Keywords: Parallel slide gate valve, welded parallel slide gatevalve, flanged parallel slide gate valve,fluid control device, gate valve

Description: The parallel slide gate valve comes with either a single discor double disc. This product is widely employed for the flow control of water,steam, oil, natural gas, and corrosive mediums.

Links:https://www.globefindpro.com/products/76544.html