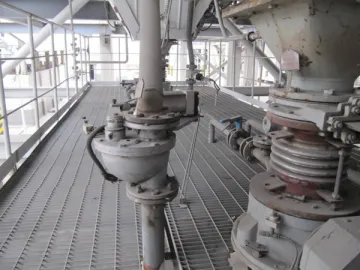

The Tank Bottom Angle Valve

The dump valve is mainly used at the bottom of the reaction still, storage tank and other containers to discharge the material or take samples. The product can be welded or installed on the container through the flange at the bottom of the valve. With this driven dump valve, the medium residue accumulation at the outlet of the container can be avoided.

Features

1. This range of manual control dump valve is manufactured in integrated structure.

2. There are Y type and angle type structure for your selection. Moreover, the bottom of the dump valve can be designed with tube joint according to customer’s requirement.

3. Provided with anti-rotation mechanism, the rectilinear motion of the valve stem can be assured.

4. The protection plate makes for the outstanding erosion resistance and corrosion resistance of the valve body.

5. The sealing surface of the valve seat and the valve disc is made of over laying cemented carbide or painted with tungsten carbide. The auxiliary line sealing guarantees the reliability of the sealing performance.

6. The dump valve is anti-scaling.

Technical Parameters

| Size | 2"-14" DN50-DN350 |

| Pressure | Class 150-Class 600 / PN1.0-PN16 |

| Material of Valve Body | WCB(A105), WC6, WC9, LCB, CF8(304), CF8M(316), CF3(304L), CF3M(316L), etc. |

| Connection Type | Flange, weld, etc. |

| Drive Mode | Manual, Electric |

| Design Standard | ASME、 DIN |

Applications

Chemical industry

Nonferrous industry

Links:https://www.globefindpro.com/products/76545.html