SAWH Steel Pipe Manufactured in Two-step Process

Overview

To overcome the problems like poor dimensional accuracy and low productivity during producing the submerged arc welding steel pipe, SHENGLI imports top-of-the-range equipment from Germany, aiming to manufacture the SAWH steel pipe of high quality.

This oil pipe is manufactured in two-step process. In another word, forming and welding are separately performed, which effectively avoids mutual interference of the two crafts, and also maximizes the preponderance of both crafts. Meanwhile, the quality of weld bead is well guaranteed and residual stress is sound controlled.

By adopting this manufacturing technique, the inherent defects of our SAWH steel pipe are completely improved. Organic combination of high-speed forming and low-speed welding largely enhances product output and quality. Currently, this steel gas pipe is extensively applied to ashore oil and gas transportation.

Parameters

1. Outside diameter: φ610-φ1626mm

2. Length: 8-15m

3. Maximum wall thickness: 25.4mm

4. Maximum steel grade: X80

5. Standard: API Spec. 5L, GB/T9711, technical specifications required by customer

Work Flow

→ → → → → → → → → → → → → → → → → → → → → →

Technical Advantages

1. As the forming process is optimized, the SAWH steel pipe is accurately formed in geometrical shape, and straightness, roundness and diameter of this HSAW steel pipe also reach high precision. Meanwhile, vibration caused during forming process is effectively avoided, and thereby welding head remains stable.

2. Longitudinal submerged arc welding technique is adopted, thus improving pipe quality.

3. In forming process, gas shielded welding craft is utilized for continuous tack welding, which is convenient for parameter adjustment and also improves the accuracy of forming size.

4. Productivity of traditional helical welded pipe depends on submerged arc welding speed. As our SAWH steel pipe is manufactured in two-step process, forming speed is improved and won't be affected by welding speed.

5. Our production line takes advantage of automation technology to reduce misoperation and ensure pipe quality.

6. Elastic recovery of steel pipe can be accurately controlled, and thus residual stress is effectively controlled.

7. Butt weld quality is guaranteed. After internal and external welding, CNC welding station will perform external welding. Then, ultrasonic inspection for the SSAW steel pipe, T-shape weld joint polishing and X-ray inspection are conducted. Hence, qualification rate of steel pipe is improved.

Links:https://www.globefindpro.com/products/76566.html

-

Bidirectional Rotary Ball Valve

Bidirectional Rotary Ball Valve

-

Dump Valve for Coal Slurry

Dump Valve for Coal Slurry

-

UV Printer for Acrylic

UV Printer for Acrylic

-

SAWH Steel Pipe Manufactured in One-step Process

SAWH Steel Pipe Manufactured in One-step Process

-

Electronic Jacquard Spare Parts

Electronic Jacquard Spare Parts

-

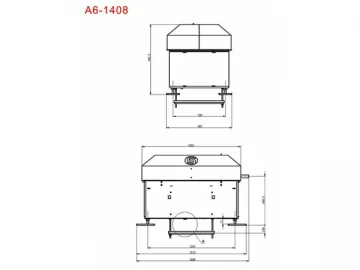

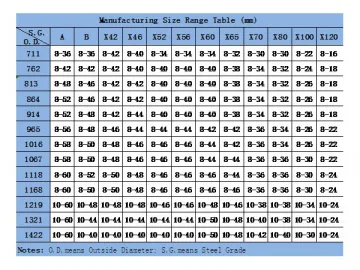

A6 Series of Electronic Jacquard

A6 Series of Electronic Jacquard

-

SAWL Steel Pipe

SAWL Steel Pipe

-

Lift Check Valve

Lift Check Valve

-

S8 Series of Electronic Jacquard

S8 Series of Electronic Jacquard

-

Y Pattern Globe Valve for Slurry Control

Y Pattern Globe Valve for Slurry Control

-

UV Printer for Aluminum Composite Panel

UV Printer for Aluminum Composite Panel

-

UV Printer for Leather

UV Printer for Leather