Straight-through Globe Valve

Straight-through Globe Valve

The straight-through globe valve is suitable for the medium such as water, steam, oils and other corrosive product. The medium control is completed through the movement of the valve disc.

Features

1. According to API standard and BS, there is a back seat provided for the manual control straight-through globe valve.

2. The stud for connection, as well as the replaceable valve seat bolted to the electric straight-through globe valve, is conducive to easy maintenance of the product.

3. The reliable packing seal of the straight-through globe valve can effectively prevent medium from leakage.

Technical Parameters

Design and Manufacturing Standard | ANSI/ASME B16.34, BS1873, GB/T 12235 |

Standard of Structure Length | ANSI/ASME B16.10 |

Flange Connection Standard | ANSI/ASME B16.5 for NPS≤24", ASME B16.47A/MSS SP-44 for NPS>24". |

Weld Standard | ANSI/ASME B16.25. |

Norminal Diameter | 2"-16" |

Pressure | Class 150-Class 600 |

Material of Valve Body | WCB(A105), WC6, WC9, LCB, CF8(304), CF8M(316), CF3(304L), CF3M(316L), etc. |

Material of Sealing Surface | Rubber, teflon, cemented carbide, etc. |

Connection Type | Flanged globe valve, welded globe valve |

Drive Mode | Manual drive, electric drive, or pneumatic drive |

Applications of the Pneumatic Globe Valve

Petroleum industry

Chemical industry

Electric power industry (,“9-3”)

Metallurgical industry

(,PDF(),pdf,:http://cn-changlin.com/wheel-loader-937h.html)

Title: Straight-through Globe Valve︱There is a back seat particularly offered for the globe valve according to API standard and BS. The stud makes for the convenient maintenance of the product.

Translation:

Straight-through GlobeValve

The straight-through globe valve is suitable for mediums such as water, steam,oils and corrosive products. The medium control is completed through themovement of the valve disc.

Features

1. Accordingto API standards and BS, there is a back seat provided for the manual control straight-through globe valve.

2. The stud for connection, as well as thereplaceable valve seat bolted to the electricstraight-through globe valve, isconducive to easy maintenance of the product.

3. The reliable packing seal of the straight-through globe valve caneffectively prevent medium leakage.

Technical Parameters

| Design and Manufacturing Standard | ANSI/ASME B16.34, BS1873, GB/T 12235 |

| Standard of Structure Length | ANSI/ASME B16.10 |

| Flange Connection Standard | ANSI/ASME B16.5 for NPS≤24", ASME B16.47A/MSS SP-44 for NPS>24". |

| Weld Standard | ANSI/ASME B16.25. |

| Nominal Diameter | 2"-16" |

| Pressure | Class 150-Class 600 |

| Material of Valve Body | WCB(A105), WC6, WC9, LCB, CF8(304), CF8M(316), CF3(304L), CF3M(316L), etc. |

| Material of Sealing Surface | Rubber, Teflon, cemented carbide, etc. |

| Connection Type | Flanged globe valve, welded globe valve |

| Drive Mode | Manual drive, electric drive, or pneumatic drive |

Applicationsof the Pneumatic Globe Valve

Petroleum industry

Chemical industry

Electric power industry (,“9-3”)

Metallurgical industry

(,PDF(),pdf,:http://cn-changlin.com/wheel-loader-937h.html)

Title:Straight-through Globe Valve︱QUANSHUN

Keywords: Straight-through globe valve, pneumatic globe valve, flanged globevalve, welded globe valve, fluid control equipment

Description: There is a back seat particularly offered for the globe valveaccording to API standard and BS. The stud makes for the convenient maintenanceof the product.

Links:https://www.globefindpro.com/products/76576.html

-

Professional Cordless Drill

Professional Cordless Drill

-

Solenoid Paint Sprayer

Solenoid Paint Sprayer

-

Garden Shredder

Garden Shredder

-

Professional HLVP Paint Sprayer

Professional HLVP Paint Sprayer

-

Grass Trimmer

Grass Trimmer

-

Professional Angle Grinder

Professional Angle Grinder

-

UV Printer for Ceramics

UV Printer for Ceramics

-

Steam Trap

Steam Trap

-

UV Printer for Glass

UV Printer for Glass

-

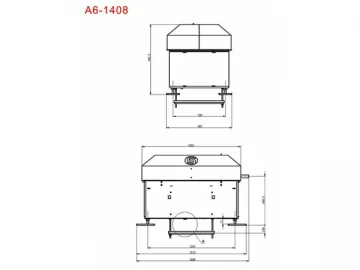

A6 Series of Electronic Jacquard

A6 Series of Electronic Jacquard

-

Electronic Jacquard Spare Parts

Electronic Jacquard Spare Parts

-

SAWH Steel Pipe Manufactured in One-step Process

SAWH Steel Pipe Manufactured in One-step Process