CBB65 Series PP Film Capacitor

The CBB65 series PP film capacitor use metalized zinc-aluminium film (the edges are thickened) as the electrodes and dielectric. After coiled by a coiler, the film is cased by an alluminium enclosure, which will be filled with castor oil later to maintain the vacuum state in the enclosure. Thus the polypropylene film capacitor becomes high temperature resistant, while its performance is better and the service life is longer.

By using the second generation anti-explosion technique, the safety and performance of this polymer capacitor are greatly enhanced. Thus far, this kind of electronic component have got the CE certificate and certified by many third party certification institutes like UL, CQC, CB, and TUV. Besides, custom products are also available. Currently, about 300000 pieces of products are sold to the Middle East and Southeast Asia each year.

The CBB65 series PP film capacitor is suitable for the running of 50/60Hz AC motor. For example, it can be used as air conditioner capacitor, washing machine motor capacitor, electric fan capacitor, oven capacitor,and so on.

Parameter Operating condition| Standard | GB3667.1-2005 (Chinese national standard) |

| Climate types | 40/70/21 |

| Capacitance allowance | ±5% |

| Insulation resistance | ≥3000Sµ FI.R |

| Loss tangent | ≤0.002 (50-100Hz) |

Technical detail

| CBB65A Series | |

| Structure | |

| Dielectric material | Both way stretchable polypropylene film |

| Electrode material | Metallized plating (Zn/AL) |

| Encapsulation material | Round aluminum casing and iron lid |

| Dipping material | Vegetable oil (Up to the RoHS standard) |

| Installation | Flat base or M8 stud (Max. torque: 5Nm) |

| Size range | Diameter: 40 … 63.5mm, Height: 70 … 130mm |

| Technical parameter | |

| Rated capacitance, CR | Monocase: 1μf, 2μf … 150μf; Combination: 1 1μf … 85 15μf |

| Rated voltage (AC), VR | 250V-500V |

| Rated frequency,FR | 50/60Hz |

| Capacitance allowance | ±5% (Products with other allowances are also available according to your requirement) |

| Degree of protection | P1, P2 (According to IEC60252-1) |

| Maximum allowable value | |

| Maximum allowable voltage | 1.1×VR (VR=rated voltage) |

| Maximum allowable current | 1.3×IR (IR=rated current) |

| Test data | |

| AC withstanding voltage between terminals, VTT | 2.0×VR, 2s |

| AC withstanding voltage between terminals and Encapsulation | 3000V, 2s |

| Insulation resistance (Rlns) or time constant (T) (20℃, humidity≤65%) | ≥10,000s |

| Dissipation tan 6(20 ℃ ) | ≤45×10-4 (1000Hz) |

| dV/dt(max) | 10V/us |

| Environment | |

| Temperature range (Tmin/Tmax) | -40/ 85℃, -25/ 85℃, -25/ 70℃ |

| Testing period (Damp and hot test) | 21 days |

| Performance | |

| Safety | Overvoltage separation (Figure 1); max. allowance fault current: 10000A; up to UL810 standard |

| Feature | Our capacitor comes with a metal film produced by the vacuum deposition technique. Then the self-healing performance is enhanced, the heat generated during the working process can be largely lowered, and the service life can be lengthened to a degree. |

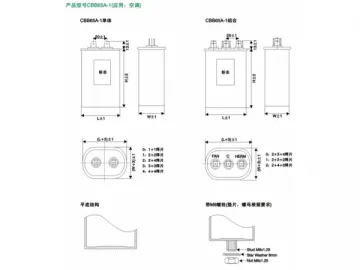

Model: CBB65A (Application: air conditioner, washing machine, lighting equipment, and so on)

| CBB65A monocase | CBB65A combination | ||

| ① Toque: 5Nm | ② Toque: 5Nm | ||

| 0: 1 1 type soldering terminals 1: 2 2 type soldering terminals 2: 2 4 type soldering terminals 3: 3 3 type soldering terminals 4: 4 4 type soldering terminals | 0: 2 3 4 type soldering terminals 1: 1 2 3 type soldering terminals 2: 1 2 4 type soldering terminals 3: 1 3 4 type soldering terminals | ||

| sheath line 3 plug-in ports (6.8×0.8mm) | sheath line plug-in port (optional, 6.8×0.8mm) | ||

| ③ Black solidified epoxy resin | ③ Black solidified epoxy resin | ||

| Flat base | M8 stud custom washer and nut | ||

| CBB65A-1 monocase | CBB65A-1 combination | ||

| 0: 1 1 type soldering terminals 1: 2 2 type soldering terminals 2: 2 4 type soldering terminals 3: 3 3 type soldering terminals 4: 4 4 type soldering terminals | 0: 2 3 4 type soldering terminals 1: 2 2 2 type soldering terminals 2: 2 4 3 type soldering terminals | ||

| Flat base | M8 stud custom washer and nut | ||

Links:https://www.globefindpro.com/products/76708.html

-

X-Ray Film Viewer

X-Ray Film Viewer

-

KH Series Four Point Contact Ball Bearing

KH Series Four Point Contact Ball Bearing

-

Self-Ballasted Germicidal UV Bulbs

Self-Ballasted Germicidal UV Bulbs

-

Double Ended Germicidal Lamps (Preheat Start) - T5 2P

Double Ended Germicidal Lamps (Preheat Start) - T5 2P

-

S-2 Series Dual Worm Slewing Drive

S-2 Series Dual Worm Slewing Drive

-

Desktop UV Lamp

Desktop UV Lamp

-

Worm and Pinion Driven Slewing Drive

Worm and Pinion Driven Slewing Drive

-

Ozone Air Disinfection System

Ozone Air Disinfection System

-

Stretcher

Stretcher

-

PE Dry Bulk Container Liner

PE Dry Bulk Container Liner

-

High Output UV Germicidal Lamps

High Output UV Germicidal Lamps

-

PP Dry Bulk Container Liner

PP Dry Bulk Container Liner