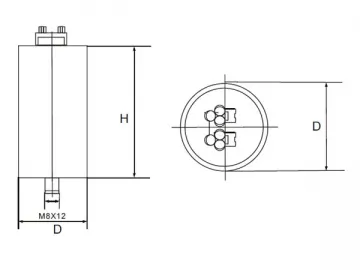

CBB60 Series Running Capacitor

CBB60 AC metallized polypropylene film capacitor

The dielectric of the CBB60 series running capacitor is polypropylene film whose edges has been thickened by zinc-aluminium. The internal components of the run capacitor are wrapped by inflaming retarding epoxy resin, so the self-curing performance is great. This series run capacitor mainly comes with a cylinder shape, while the electric dissipation is quite small (equal to or less than 1.5×10-3, 1000Hz). The maximum capacitance could reach 130μf.

Our CBB60 series running capacitor features with excellent stability, great anti-moisture performance and cost effectiveness. It can be widely used for 50/60Hz AC motor as air compressor capacitor, air conditioner capacitor, as well as capacitors for jetting machine, running machine, electric DIY tool, exhaust blower, grinding machine, woodworking machine, garden machine, fridge, washing machine, electric fan, and so on.

Parameter Operating condition| Altitude | No more than 2000m |

| Residue voltage | The residue voltage of the capacitor can not be higher than 10% rated voltage when it is being put into use. |

| Environment | No conductive dust, no corrosive gas, no combustible around |

| Operating temperature | -40℃~ 70℃ |

| Operating time | Continuous operation |

| CBB60 series (Application: pump, mower, ceiling fan, and so on) | |

| Structure | |

| Dielectric material | Both way stretchable polypropylene film |

| Electrode material | Metallized plating (Zn/AL) |

| Encapsulation material | Plastic casing and lid |

| Dipping material | Epoxy resin |

| Connecting port | sheathed line plug-in port (6.3×0.8mm or 4.8×0.8mm, with outer insulating sheath) or #250 soldering terminal |

| Installation | Flat base or M8 stud (Max. torque: 5Nm) |

| Size range | Diameter:26-60mm, Height: 60-120mm |

| Technical parameter | |

| Rated capacitance (Monocase), CR | 1μf, 2μf …130μf |

| Rated voltage (AC), VR | 200V-500V |

| Rated frequency, FR | 50/60Hz |

| Capacitance allowance | ±5% (Products with other allowances are also available according to your requirement) |

| Degree of protection | P0 (according to IEC60252-1) |

| Maximum allowable value | |

| Maximum allowable voltage | 1.1×VR (VR=rated voltage) |

| Maximum allowable current | 1.3×IR (IR=rated current ) |

| Test data | |

| AC withstanding voltage between terminals, VTT | 2.0×VR, 2s |

| AC withstanding voltage between terminals and Encapsulation | 3000V, 2s |

| Insulation resistance (Rlns) or time constant (T) (20℃, humidity≤65%) | ≥10,000s |

| Disipation tan 6 (20℃ ) | ≤1.5×10-3 (1000Hz) |

| dV/dt(max) | 10 V/us |

| Environment (IEC60068-1) | |

| Temperature range (Tmin/Tmax) | -25/ 85℃, -25/ 70℃ |

| Testing period (Damp and hot test) | 21 days |

| Performance | |

| Feature | The product comes with a metal film added by the vacuum deposition technique to increase the self-healing performance. Thus the heat generated during the working process can be largely lowered, and the service life can be extended to a great degree. |

Links:https://www.globefindpro.com/products/76723.html

-

Double Ended Germicidal Lamps (Preheat Start) - T6 2P

Double Ended Germicidal Lamps (Preheat Start) - T6 2P

-

Underarm Crutch

Underarm Crutch

-

Movable UV Lamp

Movable UV Lamp

-

Wall Mounted UV Lamp

Wall Mounted UV Lamp

-

CD239 Series High Current Capacitor

CD239 Series High Current Capacitor

-

CBB80 Series Dry Capacitor, Immersed Capacitor

CBB80 Series Dry Capacitor, Immersed Capacitor

-

Double Ended Germicidal Lamps (Preheat Start) - T8 2P

Double Ended Germicidal Lamps (Preheat Start) - T8 2P

-

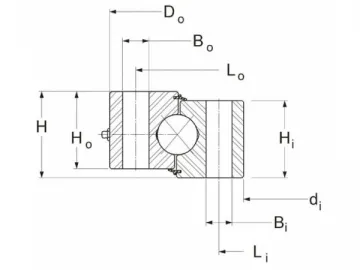

XT Series Four Point Contact Ball Bearing

XT Series Four Point Contact Ball Bearing

-

Specific Germicidal Lamp Bases

Specific Germicidal Lamp Bases

-

Worm Gear Reducer

Worm Gear Reducer

-

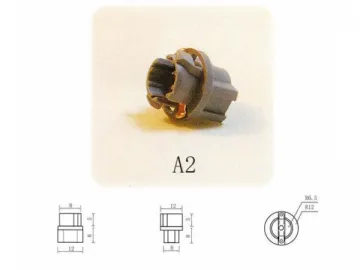

Instrument Light Socket

Instrument Light Socket

-

Ozone Disinfection System for Hospital Bed

Ozone Disinfection System for Hospital Bed