High Speed Plastic Mixer

LANGYI's high-speed plastic mixer is mainly used for batching, mixing, coloring, and drying of various resins, such as PE, PP, and PVC. Another use of our mixer is in the drying and dewatering of ABS, PC, or other engineering plastics prior to the forming process. The plastic mixing equipment is also suitable for blending of phenolic resins.

As an ideal piece of plastics processing equipment, the mixer would automatically cool down the hot resin and prevent it from caking once the mix is done. During this process, residual gas is removed from the mixer. Unique to this compact plastic mixer design is the PLC system which simplifies manual operation by automating basic procedures, making production easier and more reliable.

Features

1. At the initial design stage, the plastic mixer is optimized so that it fits in with customer's factory.

2. There is little gap between the impeller vane and mixer wall. This design prevents sticky resin from adhering to the mixer wall as it would be scrapped off by the rotary impeller.

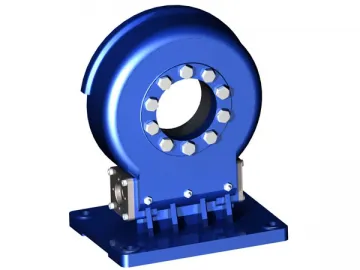

3. The plastic mixer comes standard with a drive box to ensure stable operation.

4. Main shaft seal features a special structure, and is available with both electrical and pneumatic heating functions.

5. Electric parts are of well-known brands, offering automatic control and high reliability.

6. Options: pulse-jet dust collector, feeder

Technical Specifications

| Model No. | Total Volume | Effective Volume | Rotational Speed of Impeller | Motor and Heating Power | Water Consumption | Heating Method | Materials Discharging Method | Dimensions | Capacity | Mixing Time | Cooling Time |

| SRLZ50/100 | 50/100 | 32/75 | 750/1500/180 | 7/11/5.5 | 3t/h | Electric Heating/ Mechanical Friction | Manual/ Pneumatic | 2300/1800/1900 | 2.8T | 8-10 min/tank | 6-8 min/ tank |

| SRLZ100/200 | 100/200 | 75/160 | 650/1300/180 | 14/22/7.5 | 3.5t/h | Electric Heating/ Mechanical Friction | Manual/ Pneumatic | 2500/2000/2200 | 3T | 8-10 min/tank | 6-8 min/tank |

| SRLZ200/500 | 200/500 | 150/320 | 475/950/130 | 30/42/11 | 5t/h | Electric Heating/ Mechanical Friction | Manual/ Pneumatic | 4580/2240/2470 | 3.5T | 8-10 min/tank | 6-8 min/tank |

| SRLZ300/600 | 300/600 | 200/360 | 475/950/130 | 40/55/11 | 3-8t/h | Electric Heating/ Mechanical Friction | Pneumatic | 4580/2240/2500 | 3.8T | 8-10 min/tank | 6-8 min/tank |

| SRLZ300/1000B | 300/1000 | 200/640 | 475/950/50 | 40/55/11 | 5.8t/h | Electric Heating/ Mechanical Friction | Pneumatic | 4600/3000/4050 | 4.2T | 8-10 min/tank | 6-8 min/tank |

| SRLZ500/1000A | 500/1000 | 375/650 | 430/860/60 | 47/67/18.5 | 5.8t/h | Electric Heating/ Mechanical Friction | Pneumatic | 4600/3000/4050 | 5.8T | 8-10 min/tank | 6-8 min/tank |

| SRLZ500/1000B | 500/1000 | 375/640 | 430/860/60 | 55/75/15 | 6.8t/h | Electric Heating/ Mechanical Friction | Pneumatic | 4600/3000/4050 | 7.8T | 8-10 min/tank | 6-8 min/tank |

| SRLZ500/1600B | 500/1600 | 375/1200 | 430/860/50 | 55/75/18.5 | 10t/h | Electric Heating/ Mechanical Friction | Pneumatic | 4600/3000/4050 | 7.3T | 8-10 min/tank | 6-8 min/tank |

| SRLZ800/1600A | 800/1600 | 600/1024 | 500/50 | 75/30 | 10t/h | Electric Heating/ Mechanical Friction | Pneumatic | 6230/4230/4480 | 8T | 8-10 min/tank | 6-8 min/tank |

| SRLZ800/2000B | 800/2000 | 600/1500 | 370/740 | 83/110/30 | 12t/h | Electric Heating/ Mechanical Friction | Pneumatic | 4850/3860/6550 | 7.3T | 8-10 min/tank | 6-8 min/tank |

Links:https://www.globefindpro.com/products/76772.html