Plastic Crusher

If you are in the plastics recycling industry and you have waste plastics in various shapes and sizes, this plastic crusher, or plastic shredder might be of great help to you as it breaks down your plastic bottles, blocks and strips to a manageable and reusable size. It turns these scrap materials into a valuable commodity that can be reclaimed for use in your plastics manufacturing process.

Features

1. Full steel body is sturdy, durable and able to withstand a long time of use.

2. Made of quality tool steel, the knife features a telescopic design, and can be sharpened once its gets dull. It can be used repeatedly, delivering a long service life.

3. The rotary knife holder is constructed of high-grade T7A tool steel. It is neither too brittle which would make it easy to break, nor too soft which would be easily worn down. The knife holder is secured in place by Grade 8.8 high-strength steel bolt.

4. The shredder body is of Q235A stainless steel construction with maximum wear resistance.

5. Shaft axis and end faces are precision machined using jib borer to ensure both the concentricity and perpendicularity are within the tolerance of ±0.05mm. Each part has basic holes, with its surface undergoing both rough and finish machining processes. This ensures precision and allows for high interchangeability.

6. The motor is fitted with overload protection and interlock system to ensure operating safety.

Upon your request, we can add sound insulation to the plastic shredder so that the whole unit can work quietly. For more specifications, please feel free to contact us.

Technical Specifications

| SWP Series | ||||||||

| Model No. | SWP160 | SWP200 | SWP260 | SWP360 | SWP400 | SWP560 | SWP600 | SWP-630 |

| Diameter of Rotation | 160 | 200 | 260 | 360 | 400 | 560 | 600 | 630 |

| Number of Rotary Knives | 8 | 3 | 3 | 3 | 5 | 6pcs/2sets | 15pcs /sets | 3 |

| Knife Rotational Speed (r/min) | 500 | 870 | 580 | 536 | 500 | 500 | 500 | 401 |

| Number of Stationary Knives | 2 | 2 | 2 | 2 | 2 | 4pcs/2sets | 4pcs/2sets | 2 |

| Hole Diameter of Bed Screen (mm) | ф8 | ф8 | 10 | 10 | ф10 | ф10 | ф10 | 10 |

| Shredding Capacity (kg/h) | 60-120 | 50-110 | 150-300 | 300-400 | 350-450 | 400-650 | 400-650 | 700-800 |

| Motor Power (kw) | 3 | 5 | 7.5 | 11 | 15 | 30 | 37 | 45 |

| Power Supply | 3-Phase 380V 50Hz | |||||||

| Material Inlet Diameter (mm) | 220×100 | 240×350 | 330×220 | 520×270 | 330×260×2 | 460×520×2 | 460×520×2 | 500×510 |

| Plastic Shredder Weight (kg) | 305 | 450 | 750 | 800 | 980 | 980 | 1500 | 3500 |

| PC Series | ||||||||

| Model No. | Pc300 | Pc400 | Pc500 | Pc600 | Pc800 | Pc1000 | ||

| Power (KW) | 5.5 | 7.5 | 15 | 18.5-22 | 22 | 30-37 | ||

| Shredding Chamber (MM) | φ220 × 300 | φ246 × 400 | φ265 × 500 | φ280 × 600 | φ410 × 800 | φ500 × 1000 | ||

| Number for Rotary Knives | 9 | 12 | 15 | 18 | 24 | 34 | ||

| Number of Stationary Knives | 2 | 2 | 2 | 4 | 4 | 9 | ||

| Shredding Capacity (KG/HG) | 100-200 | 200-300 | 300-400 | 400-500 | 500-600 | 600-800 | ||

| Hole Diameter of Screen (MM) | φ10 | φ10 | φ10 | φ10 | φ12 | φ14 | ||

| Inlet Diameter | 300×250 | 400×250 | 500×250 | 600×250,600×420 | 800×450 | 1000×450 | ||

| Weight (KG) | 480 | 660 | 1000 | 1500 | 1800 | 2000 | ||

Links:https://www.globefindpro.com/products/76799.html

-

Stainless Steel Kitchen Sink

Stainless Steel Kitchen Sink

-

Spiral Reinforced PVC Hose Extrusion Line

Spiral Reinforced PVC Hose Extrusion Line

-

PET/PBT Single Layer/Multi-layer Sheet Extrusion Line

PET/PBT Single Layer/Multi-layer Sheet Extrusion Line

-

PVC Hot-Cutting Granulating Line

PVC Hot-Cutting Granulating Line

-

PVC Water Supply Pipe/Drainage Pipe Extrusion Line

PVC Water Supply Pipe/Drainage Pipe Extrusion Line

-

PP/PE Recycling Line with Water Ring Granulator

PP/PE Recycling Line with Water Ring Granulator

-

Plastic Pulverizer

Plastic Pulverizer

-

Angle Valve

Angle Valve

-

Ceramic Toilet

Ceramic Toilet

-

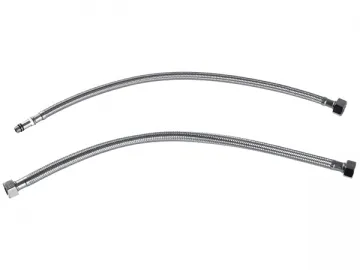

Shower Hose

Shower Hose

-

Flush Valve

Flush Valve

-

Ceramic Urinal

Ceramic Urinal