Shoe Cover Making Machine with Ultrasonic Plastic Welding System

50/60HZ Drive: AC Motor &Inverter Dimension: 2400*800*1360mm Samples Description

Jieda shoe cover making machine is specially developed by utilizing ultrasonic welding technology to replace conventional sewing method. The entire production process from raw material to finial product is controlled by PLC system. The ultrasonic system with automatic tension control provides a stable operation for shoe cover welding and elastic band placing. This ultrasonic welder is perfectly suitable for production non-woven shoe covers and PE shoe covers used in hospitals, dust-free workshops, research laboratories and other sterile environments.

PLC control system

Microcomputer controlled photoelectric sensor features high reliability and low failure rate;

Anvil wheel

Diamond anvil wheels has high wear resistance and long service life, capable of smooth feeding of materials without damage;

Aluminum machine body

The machine body is made from aluminum alloy, the compact construction provides superior look and high corrosion resistance;

Links:https://www.globefindpro.com/products/7683.html

-

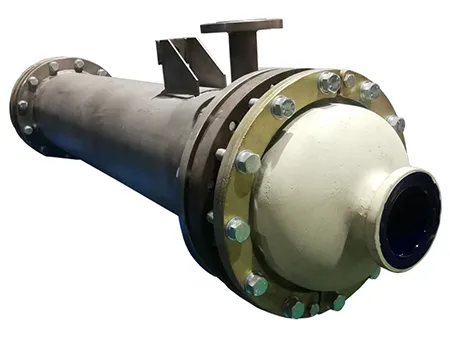

Glass Lined Piping

Glass Lined Piping

-

Automatic Airline Tag Eyeleting Machine, LM-JY5

Automatic Airline Tag Eyeleting Machine, LM-JY5

-

Automatic Dual Hang Tag Stringer, LM-LY3-CS

Automatic Dual Hang Tag Stringer, LM-LY3-CS

-

Silicon Carbide Heat Exchanger, F4/PFA Lined

Silicon Carbide Heat Exchanger, F4/PFA Lined

-

Silicon Carbide Heat Exchanger, PTFE Lined

Silicon Carbide Heat Exchanger, PTFE Lined

-

Automatic Hang Tag Elastic Stringing Machine, TL-LY8

Automatic Hang Tag Elastic Stringing Machine, TL-LY8

-

Automatic Hang Tag Elastic Stringing Machine, TL-LY5

Automatic Hang Tag Elastic Stringing Machine, TL-LY5

-

Automatic Hang Tag Stringing Machine (for Jewelry Tags), LM-LY3-P

Automatic Hang Tag Stringing Machine (for Jewelry Tags), LM-LY3-P

-

2kW IPG Fiber Laser Aluminum CNC Cutter Machine

2kW IPG Fiber Laser Aluminum CNC Cutter Machine

-

CNC Hydraulic Guillotine with Variable Rake

CNC Hydraulic Guillotine with Variable Rake

-

2-Axis NC Hydraulic Press Brake

2-Axis NC Hydraulic Press Brake

-

4-Axis Hydraulic CNC Sheet Metal Press Brake

4-Axis Hydraulic CNC Sheet Metal Press Brake