Hot Stamping Machine for Plastics

Our hot stamping machine comes in a number of models, the most popular being the OTR-300, ORT-4100 and -6100.

Model ORT-300 uses solvents as marking inks and performs stamping at low temperatures. It is available with the staticeliminator, and cleaning and glue application functions. The pressing and release motion of the hot stamping roller is pneumatically controlled. Silicon glue is applied to the roller surface for increased resistance to high temperatures. The movement of objects to be stamped is monitored so that the whole process can run smoothly, quietly with adjustable speed and easy operation. This stamping machine is mostly designed for marking the PVC wall board, door panel, foam board, laminated board, and fiberboard with beautiful patterns.

Model OTR-4100 or 6100 stamping machine is specially designed for stamping irregularly-shaped plastic profiles. Available also with pneumatic control of compression and release motion, the stamping roller is coated with silicon adhesives for resistance to high temperature and offers various stamping angles. Even more beneficial, the stamping machine is capable of automatically letting out or winding up the plastic films to be marked. The windup speed is the same with that of stamping. These two models are suitable for impressing patterns into PVC liners, and plastic profiles.

Technical Specifications

| Model No. | OTR-200/600 (for stamping theend face) | TY800-1300 | OTR-300 | OTR-4100 | OTR-5300 (for door frame) |

| Stamping Width | 200/600 mm | 100 mm | 300 mm | 100 mm | 50-300 mm |

| Stamping Speed | 1-10m/min | 2-10 m/min | 1-10 m/min | 0-10 m/min | 2-10 m/min |

| Stamping Thickness | 5-50mm | 5-100 mm | 2-40mm | 5-100mm | 5-70mm |

| Transmission Power | 1.5kw | 1.5kw | 5.5 kw | 12 kw | 1.68 kw |

| Heating Power | 2.6kw | 6kw | 10kw | ||

| Dimensions | 3650×2500× 1800mm | 6500×750× 1650mm | 4000×1200× 1900mm | 72000×750× 2000mm | 74000×750× 2000mm |

Links:https://www.globefindpro.com/products/76854.html

-

003 Series Induction Flood Light

003 Series Induction Flood Light

-

Artemis Series LED Aquarium Light

Artemis Series LED Aquarium Light

-

001 Series Induction Flood Light

001 Series Induction Flood Light

-

Plastic Winder

Plastic Winder

-

004 Series Induction Street Light

004 Series Induction Street Light

-

Apollo Series LED Aquarium Light

Apollo Series LED Aquarium Light

-

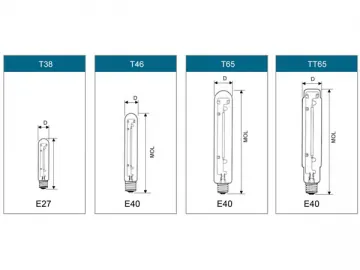

High Efficiency HPS Lamp

High Efficiency HPS Lamp

-

Noah's Ark Series LED Aquarium Light

Noah's Ark Series LED Aquarium Light

-

Classic Series LED Aquarium Light

Classic Series LED Aquarium Light

-

209 Series Induction High Bay Light

209 Series Induction High Bay Light

-

004 Series Induction Flood Light

004 Series Induction Flood Light

-

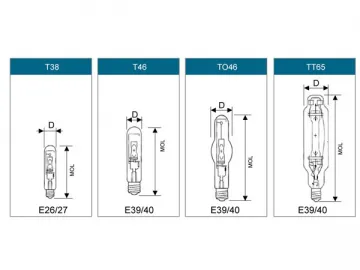

Tubular Metal Halide Lamp

Tubular Metal Halide Lamp