Energy Saving PET Sheet Extrusion Line

The single-screw extruder on this modern-design PET sheet extrusion line comes with 2 air outlets. Thanks to this air outlet design, our PET sheet production line no longer needs a separate dehumidification drying system which otherwise would have been necessary to remove the moisture contained in the PET raw stock. Therefore, a large amount of power is saved for reduced production cost.

Key Parts

Extruder, hydraulic screen changer, coat-hanger type sheet die, 3 chill rolls (for sheet compression and imparting gloss to the sheet), conveyor support (for effective cooling), 2 take-up rollers

This PET, PETG, and CPET single-layer and multi-layer sheet extrusion line represents the most advanced, reliable, and mature production line that one has ever witnessed in China. It outperforms most of its contemporaries by 30% or even higher. In addition to producing PET sheet extrusions, this plastics extrusion line is also used to make PS, PP, and PP plastic sheets.

Transparent and eco-friendly, the extruded PET sheet exhibits good workability. It is easily recyclable, and traps air between layers thereby providing good thermal insulation performance.

Technical Specifications

| Model No. | APET120-1000 | PET130-1600 |

| Sheet Width | 800mm | 1400mm |

| Sheet Thickness | 0.20-1.2mm | 0.20-1.2mm |

| Equipment Speed | 15m/min | 15m/min |

| Roller Diameter | Ø400mm | Ø500mm |

| Production Capacity | 400kg/h | 600kg/h |

Links:https://www.globefindpro.com/products/76956.html

-

Molecular Sieve

Molecular Sieve

-

Activated Alumina

Activated Alumina

-

Ammonia Decomposition Catalyst

Ammonia Decomposition Catalyst

-

Methanation Catalyst

Methanation Catalyst

-

Coal Mill

Coal Mill

-

Cement Mill

Cement Mill

-

Heat Resistant Reforming Catalyst

Heat Resistant Reforming Catalyst

-

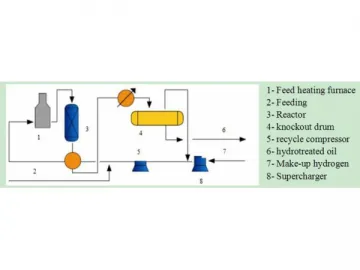

Light Distillate Hydrotreating Catalyst

Light Distillate Hydrotreating Catalyst

-

Primary Reforming Catalyst

Primary Reforming Catalyst

-

Maleic Anhydride Catalyst Carrier

Maleic Anhydride Catalyst Carrier

-

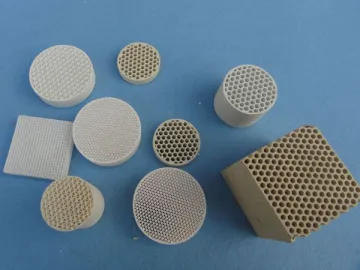

Honeycomb Ceramic Packing

Honeycomb Ceramic Packing

-

Diesel Deep Hydrotreating Catalyst

Diesel Deep Hydrotreating Catalyst