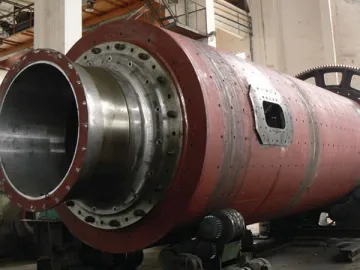

Vertical Raw Mill

Field use of vertical raw mill

Currently, the vertical raw mill has become quite mature in raw materials grinding. The features of Haijian vertical raw materials grinding mill are as follows:

1. The separator comes with a variety of structures, thus assuring the raw roller grinding machine of wide applications.

2. The grinding device is specially and reasonably designed.

3. Automatic deslagging function keeps the industrial grinding equipment more effective.

4. The hydraulic system is mature and reliable, ensuring convenient and easy maintenance.

5. This vertical raw mill is equipped with safe and reliable drive system and lubrication system.

6. Safe and reliable limiting device makes this roller mill more competitive.

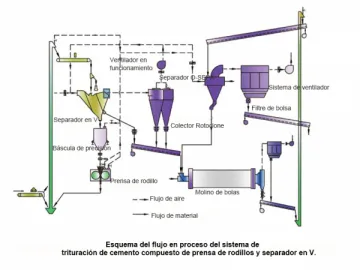

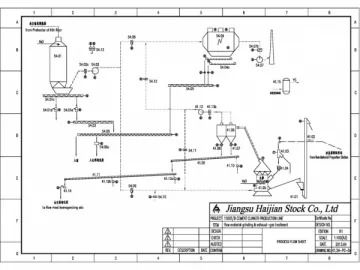

Grinding process of vertical raw mill

Technical Parameter of HJRM Vertical Raw Mill

| Models | Diameter of grinding table (mm) | Average diameter of mill roller (mm) | Quantity of mill roller | Rotating speed of grinding table(rpm) | Loading power (kW) | Standard capacity (t/h) | Guaranteed capacity (t/h) | Cement production line output(t/d) |

| HJRM16.20 | 1,600 | 1,180 | 2 | 45.77 | 200 | 26.4 | 22 | |

| HJRM18.30 | 1,800 | 1,120 | 3 | 43.16 | 330 | 43.9 | 37 | |

| HJRM19.30 | 1,900 | 1,180 | 3 | 42.01 | 380 | 50.4 | 43 | |

| HJRM20.30 | 2,000 | 1,250 | 3 | 40.94 | 430 | 57.8 | 49 | |

| HJRM22.30 | 2,200 | 1,400 | 3 | 39.04 | 580 | 77 | 65 | |

| HJRM23.30 | 2,300 | 1,450 | 3 | 38.18 | 630 | 83.5 | 71 | |

| HJRM26.30 | 2,600 | 1,600 | 3 | 35.91 | 810 | 108.1 | 92 | ~ |

| HJRM30.30 | 3,000 | 1,700 | 3 | 33.43 | 950 | 126.9 | 108 | |

| HJRM30.40 | 3,000 | 1,400 | 4 | 33.43 | 1,100 | 160.8 | 137 | ~ 2000 |

| HJRM32.40 | 3,200 | 1,400 | 4 | 32.37 | 1,200 | 168.7 | 143 | |

| HJRM32.40 | 3,200 | 1,500 | 4 | 32.37 | 1,300 | 188.7 | 160 | |

| HJRM34.40 | 3,400 | 1,500 | 4 | 31.4 | 1,400 | 197.3 | 168 | 2000 |

| HJRM36.42 | 3,600 | 1,700 | 4 | 30.52 | 1,600 | 231.7 | 197 | 2500 3000 |

| HJRM38.42 | 3,800 | 1,700 | 4 | 29.7 | 1,900 | 266 | 226 | |

| HJRM40.42 | 4,000 | 1,800 | 4 | 28.95 | 2,100 | 307 | 261 | 3500 4000 |

| HJRM43.42 | 4,300 | 1,900 | 4 | 27.92 | 2,500 | 357.4 | 304 | |

| HJRM46.42 | 4,600 | 2,060 | 4 | 27 | 3,100 | 436.2 | 371 | 4500 |

| HJRM48.41 | 4,800 | 1,900 | 4 | 26.43 | 2,700 | 386.5 | 329 | |

| HJRM48.42 | 4,800 | 2,060 | 4 | 26.43 | 3,100 | 449.8 | 382 | 4500 5000 |

| HJRM50.41 | 5,000 | 2,240 | 4 | 25.89 | 3,600 | 516.3 | 439 | |

| HJRM53.41 | 5,300 | 2,360 | 4 | 25.15 | 4,200 | 595.6 | 506 | ~6000 |

| HJRM53.42 | 5,300 | 2,500 | 4 | 25.15 | 4,400 | 630.6 | 536 | 6000 ~7000 |

| HJRM56.42 | 5600 | 2500 | 4 | 24.47 | 4,600 | 655.7 | 557 |

Remarks: Basic standard of mill selection:

(1) Medium grindability of raw material (MF) is 0.9~1.0.

(2) The Maximum moisture content of raw material is 7%.

(3) The granularity of fine material is 80μmR 12~15 %.

(4) The moisture content of fine material is 0.5~1.0 %.

(5) The above conditions are similarly suitable for limestone grinding. The specific model selection depends on the characteristics of materials.

Links:https://www.globefindpro.com/products/76990.html