Gantry Hydraulic Press

The gantry hydraulic press we provide comes with a cartridge valve integration system and independent electronic and hydraulic transmission mechanisms, which can work under the adjusting mode, double hand single recycle mode or the successive working (with material feeding device) mode. The control signals can be input through the operation penal, thus this hydraulic power press can conduct the pressing with certain stroke distance or certain pressure.

This series of gantry hydraulic press features with high toughness, great precision, and high unbalanced load tolerance. It is suitable for pressing, calibrating, stretching, bending, forming, cutting, curring metal materials. For example, as a kind of press forming machine, it can pressing powder metallurgy products, automobile components, household appliance, kitchenwares, and so on.

Feature

1. As a professional oil press provider, we can produce gantry hydraulic press that is composed by gantry, sliding block, working table, oil cylinder, and so on. The oil cylinder can move left and right for the pressing operation.

2. The blank pressing blocks on the gantry are all made of Q235 steel plate by welding, tempering and milling techniques. The inner stress has been removed through the tempering treatment.

3. The piston rod of the gantry hydraulic press is made of specially treated 45 grade steel, so the machine's service life is greatly extended.

4. The oil tank is also welded by Q235 steel plate, and at its front side, there is a pressure gage for checking and adjusting the pressure. Below the racket of the pressure gage, there is a liquidometer for checking the oil level. An oil filtering device is mounted at the oil inlet of the oil tank, guaranteeing the cleaning of the pump and the hydraulic system. An air filtering device is also fixed on the panel of the oil tank for filtering air. If you want to refill the oil, just open the upper cover, while you can clean the inside after removing the cover on the side of the oil tank in the gantry hydraulic press.

5. The hydraulic system uses a high flow rate cartridge valve. An oil filtering device is available at the oil inlet of the pump. Thus the impurities can be removed, maintaining the clear of the oil pipes. An indicator is available for displaying the oil temperature and oil level, and a air filtering device is also available for cleaning the air.

6. To avoid the sliding block falling accidentally, the gantry hydraulic press comes with hydraulically supported protecting circuit in the lower compartment of the piston type main cylinder to guarantee the safety.

Technical parameter

| Model | YHD78-1200T | YHD78-2000T | YHD78-100T | YHD78-315T | YHD78-500T | YHD78-1000T | |

| Main cylinder rated pressure | 12000KN | 20000KN | 1000KN | 3150KN | 5000KN | 10000KN | |

| Main cylinder stroke | 1200mm | 1500mm | 600KN | 500mm | 600mm | 600mm | |

| Max. opening height | 2400mm | 2800mm | 800mm | 800mm | 800mm | 1200mm | |

| Inner span | 6000mm | 6500mm | |||||

| Table effective size | Left-Right | 2600mm | 3600mm | 500mm | 1500mm | 2000mm | 3000mm |

| Front-Back | 1600mm | 1800mm | 500mm | 800mm | 1000mm | 1000mm | |

| Speed of sliding block | Empty descending | 80mm/s | 80mm/s | 50mm/s | |||

| Pressing | 10mm/s | 12mm/s | |||||

| Return | 60mm/s | 60mm/s | 70mm/s | 70mm/s | |||

| Motor Power | 90KW | 135KW | 11Kw | 15KW | 22KW | 60KW | |

Links:https://www.globefindpro.com/products/77060.html

-

Hydraulic Guillotine Shear

Hydraulic Guillotine Shear

-

CNC Hydraulic Press Brake

CNC Hydraulic Press Brake

-

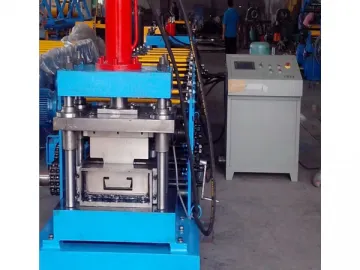

C Channel Rolling Machine

C Channel Rolling Machine

-

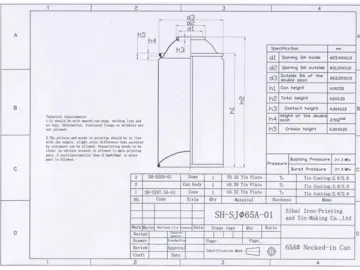

65mm Diameter Aerosol Can

65mm Diameter Aerosol Can

-

67mm Diameter Aerosol Can

67mm Diameter Aerosol Can

-

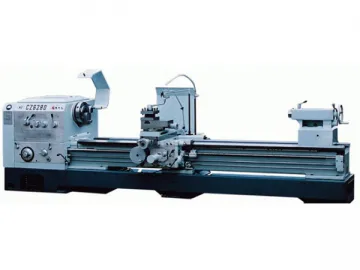

CZ6180A Series Lathe

CZ6180A Series Lathe

-

Uncoiling, Leveling and Cutting Line (Middle Size Plate)

Uncoiling, Leveling and Cutting Line (Middle Size Plate)

-

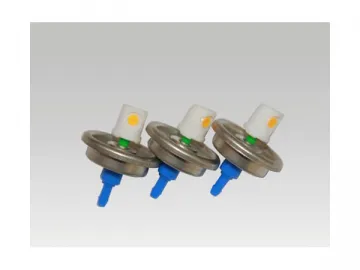

Aerosol Can Valves

Aerosol Can Valves

-

Hydraulic Corner Notcher

Hydraulic Corner Notcher

-

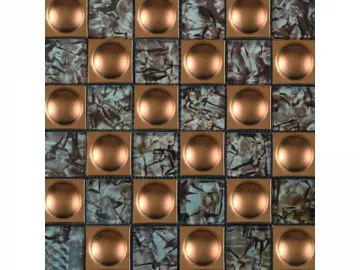

Restaurant Glass Mosaic Tiles

Restaurant Glass Mosaic Tiles

-

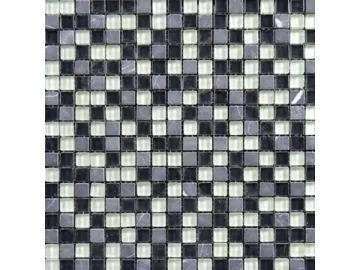

Bathroom Glass Mosaic Tiles

Bathroom Glass Mosaic Tiles

-

Double Tray Laser Marking Machine

Double Tray Laser Marking Machine