CNC Lathe

Our CK series CNC lathe comes with advanced CNC systems from famous companies at home and abroad, such as the CASUNC-901C from CASNUC, SIEMENS802D and FANUC-Oi-TD. As an excellent automated lathe, it can process workpeice powerfully and stably at a high spinning speed. The desirable precision and simple programming method allow you to do a variety of jobs effortlessly. The longitudinal and transverse feeding system is driven by an AC servo motor, and uses a pulse encoder as the feedback component.

The transverse and longitudinal rails on the CNC lathe have been subjected to high frequency quenching and fine grinding, while the rails on the bed are coated with Teflon soft band, so the frictional coefficient is very small. The speed of the main motor is controlled by adjusting both magnetic field intensity and voltage, allowing the main spindle in this CNC turning center to be adjusted in a stepless way.

Feature

1. The longitudinal repeated positioning accuracy of our CNC lathe can amazingly reach 0.013/500mm, while the transverse repeated positioning accuracy is 0.01mm. The main spindle comes with an advanced high precision and high speed bearing. The gears in the spindle box are all treated with high frequency quenching technique and their teeth are grinded, so the rotating noise is quite low. A highly sensitive DC dynamic braking system is adopted to stop the main movements effectively

2. Our CNC lathe can automatically lathe various round surfaces, like cylinder surface, tapered surface, and some other special surfaces. Besides, it can also cut slot, lathe thread, and bore and ream workpiece. The machine is both productive and versatile.

3. Subjected to high frequency quenching and fine grinding, the rails on the lathe bed is highly tough and hard. The headstock, rails, saddle, and cross slide are all thickened, and the machine is suitable for process various workpiece with certain allowance.

4. The saddle of the CNC lathe is coated with plastic, so it can move fast and the rails of the bed can be less worn. Besides, the undesirable crawling movement can also be avoided. Thus the service life and precision are both improved. The ball screw comes with an internal recycling screw rod and pre-tightened angular contact ball bearing supports. The rails and screw rod are automatically lubricated together, leading to flexible movement, little thermal deformation, and consistent precision.

5. The motor driven rest are available with four stations (vertical type), six stations (horizontal type), and eight stations (horizontal type). A precise fluted disc is used in our CNC lathe to achieve a highly precise repeated positioning performance. The handheld electronic pulse hand wheel is adopted to conveniently and accurately set the tools.

6. The tailstock comes with a rapid eccentric clamp, so the working efficiency is excellent. In the tailstock sleeve, a special device is mounted to prevent the drill bit from rotating, thus the Morse taper of the inner bore in the tailstock sleeve can be effectively protected.

7. The CNC system is from a famous domestic company. However, other CNC solutions are also optional according to your requirements. The systems are user-friendly, powerful, and stable, making the CNC lathe quite suitable for complex components and high precision components.

8. Customizable lathe solution is also available. Specifically, the center rest, hydraulic chunk, hydraulic tailstock, hydraulic straining device could come as your requirements.

9. The CNC lathe is easy to be operated, while the safety degree and appearance are both very satisfactory and the maintenance is quite simple.

Technical parameter

| Model | CK6180 | CK61100 | CK61120 (with cushion) |

| Max. swing over bed | 800mm | 1000mm | 1200mm |

| Max. swing over cross slide | 470mm | 650mm | 850mm |

| Center distance | 1500 2000 3000 4000mm | ||

| Spindle hole diameter | 105mm | ||

| Max. distance of moving tool-post | |||

| Longitudinal distance | 1500, 2000, 3000, 4000mm | ||

| Transverse distance | 450mm | 520mm | |

| Spindle speed | Four-grade stepless speed range: 14-40, 40-130, 60-200, 180-700rpm | ||

| Main motor power | 11KW or frequency conversion motor | ||

| Speed of high-speed movement | |||

| Longitudinal movement | 6m/min | ||

| Transverse movement | 3m/min | ||

| Feed resolution | |||

| Longitudinal feed | 0.01mm | ||

| Transverse feed | 0.005mm | ||

| Quantity of tools on tool-post | 4, 6 or 8 (Optional) | ||

| Positioning accuracy | |||

| Longitudinal positioning | 0.03/500mm, 0.05/2000mm | ||

| Transverse positioning | 0.02mm | ||

| Repeatability | |||

| Longitudinal dimension | 0.013/500mm 0.025/2000mm | ||

| Transverse dimension | 0.01mm | ||

| Repeatability accuracy of tool-post | 0.005mm | ||

| Net weight | |||

| Center distance: 1500mm | 4500kg | 4700kg | 4900kg |

| Center distance: 2000mm | 5000kg | 5200kg | 5400kg |

| Dimension (L*W*H) | |||

| Center distance: 1500mm | 3300*1550*1840mm | ||

| Center distance: 2000mm | 3800*1900*1960mm | ||

Links:https://www.globefindpro.com/products/77069.html

-

Universal Plate Bending Roll

Universal Plate Bending Roll

-

Hydraulic Section Bending Roll

Hydraulic Section Bending Roll

-

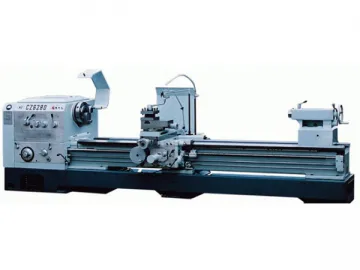

CZ6163A Series Lathe

CZ6163A Series Lathe

-

Portable CNC Cutting Machine

Portable CNC Cutting Machine

-

Hydraulic Swing Beam Shear

Hydraulic Swing Beam Shear

-

CNC Gantry Cutting Machine

CNC Gantry Cutting Machine

-

Manual Section Bending Roll

Manual Section Bending Roll

-

CZ6180A Series Lathe

CZ6180A Series Lathe

-

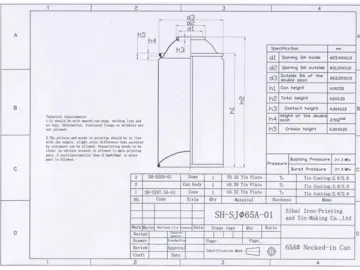

67mm Diameter Aerosol Can

67mm Diameter Aerosol Can

-

65mm Diameter Aerosol Can

65mm Diameter Aerosol Can

-

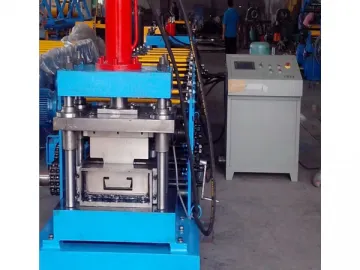

C Channel Rolling Machine

C Channel Rolling Machine

-

CNC Hydraulic Press Brake

CNC Hydraulic Press Brake