CD856A Rotary Drilling Rig

CD856A rotary drilling rig has been widely applied to construction engineering industry including highway, high-speed rail, subways and high-rise buildings, as well as large factories of steel and electricity.

As the representative model of small torque rotary drilling rig, this versatile hydraulic drilling machine has been exported to South Asia, Southeast Asia, West Asia and Eastern Europe.

Advantage

1. We utilize universal joint to maintain the connection between drill rod and connecting arm, whereby the drill rod is allowed for ±3° side raking, as well as forwards and backwards adjustments. Moreover, the verticality of drill rod is also ensured even in rugged terrains.

2. Hydraulic luffing cylinder and connecting arm form a triangle structure, thus promoting stability and performance.

3. Our rotary drilling rig is highly distinguished by outstanding energy efficiency. Based on same drilling diameter and depth, other deep foundation machines at same price level consume 3.3 to 3.8l/m, while our product only needs 1.6 to 1.85l/m!

Specification

| Drilling diameter | mm | 600 to 1500 | |

| Max. drilling depth | m | 56 | |

| Overall dimension | Drilling position | mm | 16500 × 3200 × 6720 |

| Transport position | mm | 13550 × 3200× 3200 | |

| Overall weight | kg | 38000 | |

| Engine | Model | Cummins B5.9-C | |

| Rated power | kW/rpm | 112 | |

| Design | Turbocharged direct injection | ||

| Drill head | Max. torque | kN.m | 80 |

| Speed | r/min | 1 to 22 | |

| Pull-down cylinder | Max. push force | kN | 150 |

| Max. pull force | kN | 100 | |

| Max. stroke | m | 2 | |

| Main winch | Max. pull force | kN | 120 |

| Max. pull speed | m/min | 70 | |

| Diameter of steel wire rope | mm | 24 | |

| Auxiliary winch | Max. pull force | kN | 60 |

| Max. pull speed | m/min | 50 | |

| Diameter of steel wire rope | mm | 18 | |

| Mast rake | Raking angle | ° | ±3 (side raking) |

| Forwards: 90, backwards: 6 | |||

| Base carrier | Max. travel speed | km/h | 3 |

| Max. grade ability | 40% | ||

| Min. ground clearance | mm | 430 | |

| Track shoe width | mm | 800 | |

Links:https://www.globefindpro.com/products/77182.html

-

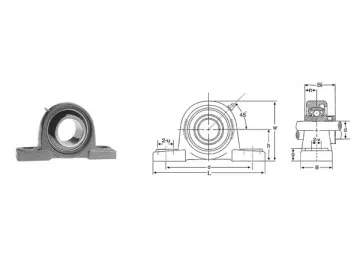

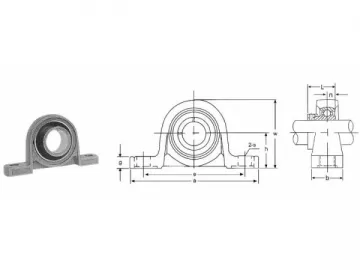

UCP200 Pillow Block Bearing Units

UCP200 Pillow Block Bearing Units

-

Flange Cartridge Bearing Units

Flange Cartridge Bearing Units

-

Stainless Steel Wire Netting for Animal Enclosure

Stainless Steel Wire Netting for Animal Enclosure

-

FD1565 Rotary Drilling Rig

FD1565 Rotary Drilling Rig

-

Trailer ABS

Trailer ABS

-

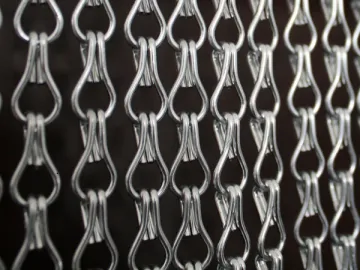

Beaded Curtain, Chain Link Curtain

Beaded Curtain, Chain Link Curtain

-

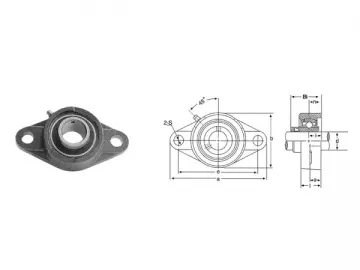

UCFL300 2 Bolt Flange Bearing Units

UCFL300 2 Bolt Flange Bearing Units

-

FD820 Rotary Drilling Rig

FD820 Rotary Drilling Rig

-

UCP300 Pillow Block Bearing Units

UCP300 Pillow Block Bearing Units

-

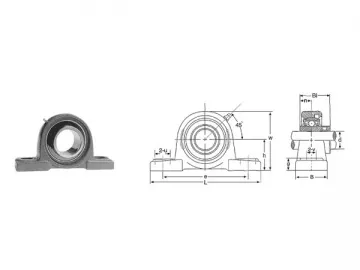

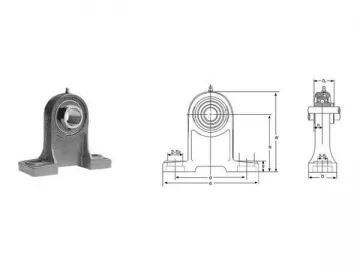

Pedestal Base Pillow Block Units

Pedestal Base Pillow Block Units

-

KP000 Zinc Alloy Pillow Block Bearing

KP000 Zinc Alloy Pillow Block Bearing

-

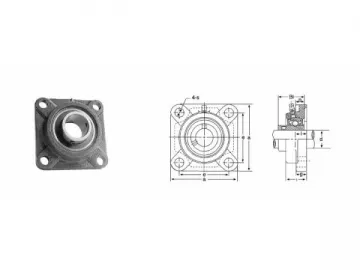

UCF300 4 Bolt Flange Bearing Units

UCF300 4 Bolt Flange Bearing Units