QT12-15 Brick Making Machine

Applications

QT12-15 brick making machine, also called baking-free brick machine, is widely used to produce hollow brick, large-scale brick, special-shaped brick, etc. By means of changing mould, it can produce various types of bricks such as colored paver brick, brick for grass seeding, environment friendly brick, porous brick, standard brick, heat insulating brick, lightweight ceramsite brick, polished tile, etc.

Additionally, it can be customized to produce various cement products for highway and railway, supporting products for landscape architecture of municipal engineering, as well as products made of construction waste. This baking free brick making machine is the main production equipment of large-scale cement products manufacturers.

Features

1.Owing to the usage of hydroform method, the brick molding equipment features excellent stability and high production capacity. In addition, end products boast compact structure.

2. The intelligent control system is designed with a large color touch screen which can achieve man-machine conversation. Furthermore, there are tens of operational modes stored in the computer to choose from, so the operation is so simple. All the control circuit apparatus are of international brands such as FUJI, OMRON, etc.

3. The brick making machine adopts hydraulic motor to transmit vibration, resolving the problem of motor heating. Meanwhile, it comes with a remote communication control system which provides great convenience for remote supervision, fault inquiry, system upgrade, etc.

4. The feeder is designed to be able to move in horizontal direction, which can make feeding more uniform and precise. And it is suitable for feeding materials into differently shaped mould.

5. The large capacity oil pump is designed with built-in strong cooler which can achieve fast cooling of hydraulic oil and prolong service life of hydraulic components, thus ensuring production stability in high temperature condition.

6. The pallet conveyer of this brake-free brick making machine features crank connecting link for conveying the pallet. This conveying method can ensure just molded bricks hard to bread.

7. It is designed with a specialized depiler to feed materials which can implement different feeding for different blocks. That will keep intensity, uniform density, and appearance for the end products, and also improve production efficiency.

8. The adjustable control cabinet comes with automatic and manual electric plates. When the automatic electric plate breaks down in production, the manual one can immediately replace it to keep the machine operating instead of shut it down. Hence, normal and continuous production can be achieved.

| Model | Product category | Size(mm) | Pcs per mould | Pcs /hour | Pcs /8 hours |

| QT12-15 | Building block | 390*190*190 | 12 | 2880 | 23040 |

| Porous brick | 240*115*90 | 30 | 7200 | 57600 | |

| Standard brick | 240*115*53 | 60 | 14400 | 115200 |

Main Technical Parameters

| Model | Cycle time(s) | Pallet size(mm) | Power(kW) | Total weight(t) | Dimensions (mm) | Max. vibration frequency (r/min) |

| QT12-15 | 15 | 1310*840*40 | 46 | 13 | 8200*2300*3000 | 4800-5100 |

Links:https://www.globefindpro.com/products/77196.html

-

ABS Sensor Parts

ABS Sensor Parts

-

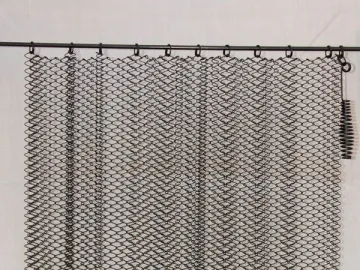

Fireplace Mesh Screen

Fireplace Mesh Screen

-

ABS Warning Light

ABS Warning Light

-

Decorative Mesh for Elevator

Decorative Mesh for Elevator

-

Bus, Coach & Truck ABS

Bus, Coach & Truck ABS

-

Metallic Cloth

Metallic Cloth

-

Stainless Steel Wire Mesh for Climbing Plant

Stainless Steel Wire Mesh for Climbing Plant

-

Metal Mesh for Industrial Filter

Metal Mesh for Industrial Filter

-

Decorative Mesh for Stair Rail

Decorative Mesh for Stair Rail

-

FD850A Rotary Drilling Rig

FD850A Rotary Drilling Rig

-

Pneumatic ABS Sensor

Pneumatic ABS Sensor

-

Decorative Mesh for Interior Wall Cladding

Decorative Mesh for Interior Wall Cladding