HZS-150 Concrete Batching Plant (150m3/h)

The HZS-150 concrete batching plant is comprised of batching system, mixing system, electronic control and other parts. It is capable of producing 150 tons of concrete every hour, and appropriate for medium and large-scale building sites, fabricated part factory and commercial concrete enterprise. Longli provides various kinds of batch mixer for road material batching and mixing, so as to satisfy different demands.

Features

1. The JS3000 twin horizontal shaft compulsory concrete mixer functions as the main machine of concrete batching plant. Powered by 2 motors, it comes with great mixing performance and high efficiency.

2. The concrete batch mix plant adopts a single hopper for aggregate weighing, and an electronic scale for precision weighing of cement, water and liquid admixture.

3. This concrete mixing plant adopts the modular structure, which facilitates installation.

4. It reduces large finished product hopper and medium aggregate hopper, lowering height and minimizing floor area.

5. According to your needs, some assembly units of concrete batching plant can be purchased from domestic or oversea enterprises, such as the burner, motor and so on.

Technical Specifications

| Model | HZS150 | |

| Structure | Modular type | |

| Power (kw) | 178 | |

| Main machine (tamping method) | Mode | Commercial cycle twin horizontal shaft compulsory mixer for concrete |

| Model | JS3000 | |

| Maximum aggregate (mm) | ≤ 150 | |

| Main machine power (mm) | 2 × 55 | |

| Hopper volume × quantity | 4 × 20 m3 | |

| Measuring mode | Accumulated measurement or individual measurement | |

| Control mode | Computer PLC professional metering device control, batch metering, intermittent work | |

| Batching precision | Aggregate≤ 2.0% Powder≤ 1.0% Water≤ 1.0% Admixture≤ 2.0% | |

| Unloading height | 3.8m (customization) | |

All Pictures

Links:https://www.globefindpro.com/products/77486.html

-

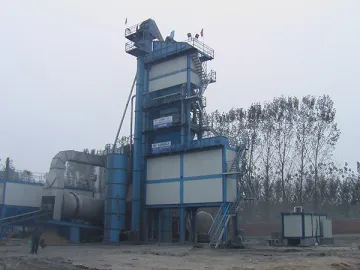

LB-2000 Asphalt Mixing Plant (120-160 Ton/h)

LB-2000 Asphalt Mixing Plant (120-160 Ton/h)

-

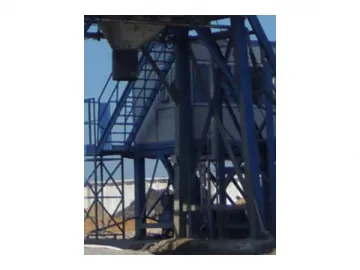

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

-

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

-

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

-

Electric Planer

Electric Planer

-

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

-

Dental Apron

Dental Apron

-

LB-3000 Asphalt Mixing Plant (180-240 Ton/h)

LB-3000 Asphalt Mixing Plant (180-240 Ton/h)

-

Cordless Drill

Cordless Drill

-

Calcium Alginate Dressing

Calcium Alginate Dressing

-

WCB400 Stabilized Soil Mixing Plant (400 Ton/h)

WCB400 Stabilized Soil Mixing Plant (400 Ton/h)

-

HZS-75 Concrete Batching Plant (75m3/h)

HZS-75 Concrete Batching Plant (75m3/h)