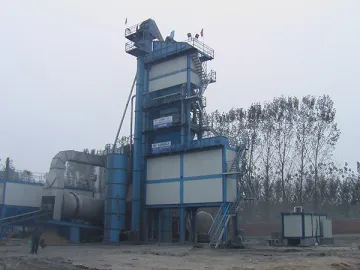

LB-2000 Asphalt Mixing Plant (120-160 Ton/h)

The LB-2000 asphalt mixing plant is a kind of batch mixer for manufacturing of asphalt material. It is capable of manufacturing 120-160 tons of asphalt concrete per hour. Its material lifting mechanism adopts the variable frequency speed regulation system, contributing to steady conveying speed. Controlled by a computer, the asphalt batch mix plant is able to weigh materials accurately. Longli can help you to design sites, install the equipment and master operation methods.

Features

1. Owing to the modular design, all the modules for the industrial batch mixing system are easy to mount or dismount.

2. The metal structure of asphalt mixing plant is mostly manufactured on the basis of steel plate stamping method, ensuring good ruggedness and high durability.

3. The hot mix asphalt plant employs the computer intelligent control system so as to facilitate operation and cut labor power.

4. The aggregate, asphalt and mineral powder are measured by a weighing sensor.

Parameters

| Model | LB-2000 |

| Productivity | 120-160 ton/h (water content≤5%) |

| Fuel | Diesel, heavy oil, natural gas, coal |

| Cold aggregate framework | Frequency control |

| Drying drum | ¢2200*7900MM |

| Burner | Proportional adjustment |

| Hot aggregate elevator | Centrifugal discharge |

| Vibrating and screening device | Five-stage |

| Metering device | Computer/Aggregate controller |

| Metering precision (static) | Aggregate±0.5% Asphalt, powder±0.25% |

| Asphalt Mixer | Forcing type |

| Filtering area | 660 M2 |

| Intermittent mixing | 2000KG/batch |

| Mixed material storage | 100T |

| Installed power | 446.5KW |

| Floor area | 38*37M |

All Pictures

Links:https://www.globefindpro.com/products/77487.html

-

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

-

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

-

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

-

Electric Planer

Electric Planer

-

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

-

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

-

HZS-150 Concrete Batching Plant (150m3/h)

HZS-150 Concrete Batching Plant (150m3/h)

-

Dental Apron

Dental Apron

-

LB-3000 Asphalt Mixing Plant (180-240 Ton/h)

LB-3000 Asphalt Mixing Plant (180-240 Ton/h)

-

Cordless Drill

Cordless Drill

-

Calcium Alginate Dressing

Calcium Alginate Dressing

-

WCB400 Stabilized Soil Mixing Plant (400 Ton/h)

WCB400 Stabilized Soil Mixing Plant (400 Ton/h)