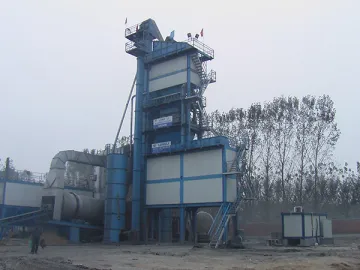

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

LB-2500

Features

Parameters

All Pictures

The production capacity of LB-2500 asphalt mixing plant is 150-200 tons every hour. It can be used to build and maintain urban and rural roads, high-grade highways, large airports and so on. Nonstandard road construction equipment is open to customization in line with your requirements.

Features

1. The cold aggregate system for the asphalt plant is controlled by a computer. The asphalt mixing plant is proud of easy operation and accurate measurement.

2. This asphalt batch mix plant can be easily installed due to modular construction.

3. Its burner is purchased from domestic or oversea companies, and comes with stable combustion performance.

4. To minimize environmental pollution, the batch mixer supports wet type and pocket type dust removal modes.

Parameters

| Model | LB-2500 |

| Productivity | 150-200 ton/h (water content≤5%) |

| Fuel | Diesel, heavy oil, natural gas, coal |

| Cold aggregate framework | Frequency control |

| Drying drum | ¢2200*8500MM |

| Burner | Proportional adjustment |

| Hot aggregate elevator | Centrifugal discharge |

| Vibrating and screening device | Five-stage |

| Metering device | Computer/Aggregate controller |

| Metering precision (static) | Aggregate±0.5% Asphalt, powder±0.25% |

| Asphalt Mixer | Forcing type |

| Filtering area | 830M2 |

| Intermittent mixing | 2500KG/batch |

| Mixed material storage | 100T |

| Installed power | 513.5KW |

| Floor area | 38*37M |

All Pictures

Scan QR to Read

Links:https://www.globefindpro.com/products/77489.html

Links:https://www.globefindpro.com/products/77489.html

Recommended Products

-

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

-

Electric Planer

Electric Planer

-

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

-

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

-

WCB600 Stabilized Soil Mixing Plant (600 Ton/h)

WCB600 Stabilized Soil Mixing Plant (600 Ton/h)

-

Electric Drill

Electric Drill

-

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

-

LB-2000 Asphalt Mixing Plant (120-160 Ton/h)

LB-2000 Asphalt Mixing Plant (120-160 Ton/h)

-

HZS-150 Concrete Batching Plant (150m3/h)

HZS-150 Concrete Batching Plant (150m3/h)

-

Dental Apron

Dental Apron

-

LB-3000 Asphalt Mixing Plant (180-240 Ton/h)

LB-3000 Asphalt Mixing Plant (180-240 Ton/h)

-

Cordless Drill

Cordless Drill

Hot Products