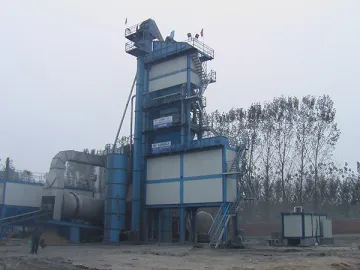

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

The maximum production capability of LB-500 asphalt mixing plant is 40 tons per hour. It can be applied in expressway, runway, city road and other projects. Our asphalt batch mix plant adopts a modular design, and comes with special structure, convenient transportation and easy installation.

Features

1. The cold aggregate framework of asphalt mixing plant employs a frequency controller, realizing automatic speed adjustment in accordance with your needs. Its conveyor belt is purchased from a well-known domestic enterprise, and comes with high quality and long working life.

2. The drying system for the modular asphalt plant is comprised of advanced domestic or oversea burner. Made of manganese steel, the lining of drying drum is resistant to abrasion and high temperature, ensuring high drying performance.

3. The asphalt mixing plant can adopt wet type or pocket type dust removal method. It performs well in dust removal, considerably reducing pollution to the surroundings. The dust may be recycled to save cost.

4. Automatically controlled by an imported microcomputer, the road building machinery does well in high stability and good reliability. The control room is equipped with the computer, printer, air conditioner, controller and other devices. Due to high automation, the asphalt mixing plant can be operated by 2-3 employees.

5. This asphalt batch mix plant has been exported to Russia,Mongolia, Kazakhstan, Kyrgyzstan,Uzbekistan and other countries, enjoying a good reputation.

Parameters

| Model | LB-1000 |

| Productivity | 60-80 ton/h (water content≤5%) |

| Fuel | Diesel, heavy oil, natural gas, coal |

| Cold aggregate framework | Frequency control |

| Drying drum | ¢1500*6500MM |

| Burner | Proportional adjustment |

| Hot aggregate elevator | Centrifugal discharge |

| Vibrating and screening device | Four-stage |

| Metering device | Computer/Aggregate controller |

| Metering precision (static) | Aggregate±0.5% Asphalt, powder±0.25% |

| Mixer | Forcing type |

| Filtering area | 412 M2 |

| Intermittent mixing | 1000KG/batch |

| Mixed material storage | 60T |

| Installed power | 251.2KW |

| Floor area | 30*28M |

All Pictures

Links:https://www.globefindpro.com/products/77492.html

-

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

-

WCB600 Stabilized Soil Mixing Plant (600 Ton/h)

WCB600 Stabilized Soil Mixing Plant (600 Ton/h)

-

Electric Drill

Electric Drill

-

Diamond Core Drill

Diamond Core Drill

-

LB-1500 Asphalt Mixing Plant (90-120 Ton/h)

LB-1500 Asphalt Mixing Plant (90-120 Ton/h)

-

WCB300 Stabilized Soil Mixing Plant (300 Ton/h)

WCB300 Stabilized Soil Mixing Plant (300 Ton/h)

-

Electric Planer

Electric Planer

-

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

-

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

-

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

-

LB-2000 Asphalt Mixing Plant (120-160 Ton/h)

LB-2000 Asphalt Mixing Plant (120-160 Ton/h)

-

HZS-150 Concrete Batching Plant (150m3/h)

HZS-150 Concrete Batching Plant (150m3/h)