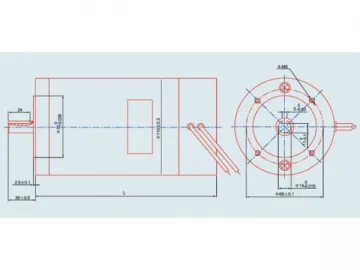

110mm Brushed Motor

Produce Code: 110mm

Features:

1.It has made the motor weight decreased a lot by having Aluminium die cast endcaps even if the motor diameter is as big as 110mm.

2.The front endcap can be machine-turned by having more pilot designs as well as mounting hole patterns for a further assembly with the applications.

3.The rugged, heavy-gauge steel housing is participated in the main materials for long-life and durability.

4.The rated torque can be designed up to 1.7N.m and it sometimes will be reasonably modified by the design engineer to create a more suitable starting torque to fit any individual application.

5.The cartridge brush assemblies have been installed into the rear endcap to allow the consumers to replace the brushes if any.

6.Dynamically balanced armatures, sealed ball bearings and rare earth magnets are necessarily to be there to maintain the high-efficiency of our brushed PMDC motors.

Applications

Our 110mm permanent magnet DC motors are widely applied to wheelchairs, golf carts, door openers, and conveyors, to name a few.

| Model | Rated Voltage (V) | Rated Current (A) | Rated Speed (rpm) | No-load Current (A) | No-load Speed (rpm) | Rated Torque (N.m) | Motor Body Length (mm) |

| SH-110DCBM006 | 12 | ≤30 | 1500 | ≤3 | 1800 | 1.7 | 200 |

| SH-110DCBM0071 | 12 | ≤34.6 | 2708 | ≤4.9 | 3270 | 1.0 | 200 |

| SH-110DCBM0072 | 24 | ≤26 | 3072 | ≤2.6 | 3350 | 1.6 | 200 |

| SH-110DCBM0081 | 48 | ≤14.3 | 3304 | ≤2.5 | 3560 | 1.6 | 200 |

| SH-110DCBM0082 | 48 | ≤14.3 | 3304 | ≤2.5 | 3560 | 1.6 | 200 |

Links:https://www.globefindpro.com/products/77663.html

-

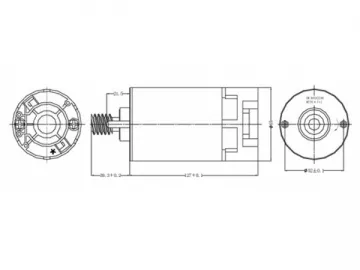

65mm Brushed Motor

65mm Brushed Motor

-

BYGHW 42mm Hybrid Stepper Motor

BYGHW 42mm Hybrid Stepper Motor

-

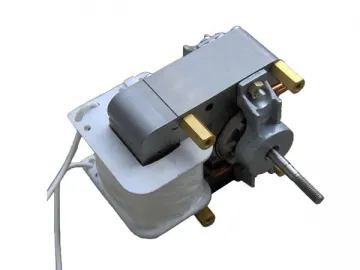

7125-1 Shaded-Pole Motor

7125-1 Shaded-Pole Motor

-

35mm PM Stepper Motor with Spur Gearbox

35mm PM Stepper Motor with Spur Gearbox

-

110AC-01 Single Phase AC Motor

110AC-01 Single Phase AC Motor

-

SP6113 Shaded-Pole Motor

SP6113 Shaded-Pole Motor

-

35mm PM Stepper Motor with Non-Captive Shaft Actuator

35mm PM Stepper Motor with Non-Captive Shaft Actuator

-

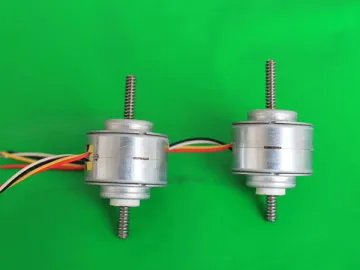

25mm PM Stepper Motor with Non-Captive Shaft Actuator

25mm PM Stepper Motor with Non-Captive Shaft Actuator

-

BYGH 57mm Hybrid Stepper Motor

BYGH 57mm Hybrid Stepper Motor

-

100mm Brushed Motor

100mm Brushed Motor

-

ZQ-TG01 DC Linear Actuator

ZQ-TG01 DC Linear Actuator

-

BYGH350 57mm Hybrid Stepper Motor

BYGH350 57mm Hybrid Stepper Motor