Frequency Inverter (Open Loop Vector Control AC Drive)

KE 300 frequency inverter provides a great way of adjusting motor speed and torque by changing the motor frequency. Frequency is directly related to the motor speed. Simply put, the faster the motor frequency, the faster the motor goes.

Traditional scalar drives lack accuracy in control due to the fact that they only control the ratio of voltage to frequency, or the V/F ratio for short. On top of that, these drives only tell the motor what to do but they have no way of knowing whether the motor does it or how well it does it.

KE300 frequency inverter is essentially a vector control AC drive or VFD that uses advanced vector control to dynamically determine the values of motor frequency and voltage. A sensor-less method used to send motor-related feedback information to the PID controller of the VFD for monitoring and analyzing the motor performance. That is why this series of VFD is sometimes called the sensor-less vector control variable frequency drive or open loop vector control AC drive.

Typical uses of our frequency inverter are in fans, water pumps or any other applications that require high energy efficiency, accurate speed regulation, quick response to sudden changes in load torque, and generating large torque at low frequency.

Features of KE300 Frequency Inverter

1. Sensorless Vector Control

Sensorless vector control allows the frequency inverter to put out 150% of the rated torque at 0.5Hz frequency. This control technique improves the flexibility of VFD in coping with changing motor loads. Our motor speed controller can be used for accurate tension control in the winding process, and overcomes the problem of uneven load distribution among multiple motors used to pull the same load.

2. Overload Protection

When the motor reaches a certain limit, the variable frequency drive only allows the motor to change its frequency without further increasing the torque when dealing with heavy duty tasks. This overload protection feature protects mechanical equipment and keep the entire operation up and running.

3. Fast, Dynamic Response to Changes in Load Torques

Dynamic response time is less than 20ms under vector control without using pulse generator.

4. Quick Current-Restriction

This feature can quickly limit the current within the allowable range, thereby avoiding alarm of over current caused by sudden addition of loads or disturbances. Our variable frequency drive reduces the possibility of frequent alarm of over current to ensure safety of our adjustable frequency drive.

5. Accurate Parameters Identification

Automatic fine-tuning of motor parameters according to the changing load conditions.

6. High Precision Torque Control

Torque control can be achieved under sensorless vector control mode. The control accuracy reaches ±10%, making it easy to complete tension control of a winch by using the frequency inverter.

7. AVR Function

When the voltage of the power grid changes, our variable speed drive can keep its output voltage constant, efficiently resolving issues of low frequency oscillation of high-power motors.

8. Dual PID Switching Function

The vector control variable frequency drive comes with two sets of PID parameters, which make it convenient to achieve close loop process control.

9. KE300 has many other powerful functions.

Please check KE300 Catalogue and KE300 User Manual for more details.

Control Functions

1. Common DC Bus: Multiple open loop vector control AC drives can share a common DC bus and their capacities are automatically balanced.

2. Torque Control: Torque control without PG is adopted.

3. Overload Protection: During operation, torque is automatically limited to prevent frequent tripping caused by over current.

4. Fault Protection: Our adjustable-frequency drive provides protection in times of fault such as overcurrent, overvoltage, undervoltage, phase loss, overload, short circuit, etc. Detailed information of operation status of the inverter is recorded. The product also has automatic recovery function.

Human Machine Interface

1. LED Display: It can show reference frequency, output frequency, output voltage, output current, etc.

2. Multifunction Key: QUICK/JOG key can also be used as multifunction key.

3. Powerful Upper Computer Software: Micno upper computer software supports uploading and downloading between frequency inverter and PC as well as real-time display.

Environmental Restrictions

1. Temperature: -10°C ~40°C . Derating of the frequency inverter is necessary if working temperature is higher than 40°C and the working temperature can not exceed 50°C . The AC drive should be derated by 4% with an increase of 1°C in temperature.

2. Humidity: ≤90%RH, no moisture condensation

3. Altitude: ≤1000m: rated power output; >1000m: derated power output

4. Storage Temperature: -20°C~60°C

5. Storage Circumstance: indoor, no direct sunlight, dust, corrosive gas, combustible gas, oil mist, steam, drip, salt, etc

Specifications

| KE300 Sensorless Vector Control Variable Frequency Drive | |||

| Input | Input Voltage | 1AC 220V±15%, 3AC 220V±15%, 3AC 380V±15% , 3AC 660V±15% | |

| Input Frequency | 47~63Hz | ||

| Output | Output Voltage | 0~Rated voltage | |

| Output Frequency | V/f : 0~3000Hz, SVC: 0~300Hz | ||

| Control Feature | Control Mode | V/f , SVC, VC, Torque control | |

| Operation Command Mode | Keypad control, Terminal control, Serial communication control | ||

| Frequency Setting Mode | Digital setting, analog setting, pulse frequency setting, serial communication setting, multi-step speed setting & simple PLC, PID setting, etc. These frequency settings can be combined and switched in various modes. | ||

| Overload Capacity | G model: 150% 60s, 180% 10s, 200% 3s P model: 120% 60s, 150% 10s, 180% 3s | ||

| Starting Torque | 0.5Hz/150% (SVC) , 1Hz/150% (V/f) | ||

| Speed Adjustment Range | 1:100 (SVC), 1:50(V/f) | ||

| Speed Control Precision | ±0.5% (SVC) | ||

| Carrier Frequency | 1.0-16.0kHz, automatically adjusted according to temperature and load characteristics | ||

| Frequency Accuracy | Digital setting: 0.01Hz Analog setting: maximum frequency ×0.05% | ||

| Torque Boost | Automatically torque boost; manually torque boost 0.1%~30.0% | ||

| V/f Curve | Three types: straight line, multiple point and square type (1.2 power, 1.4 power, 1.6 power, 1.8 power, square) | ||

| ACC/DEC Mode | Linear/S curve; four kinds of ACC/DEC time, range 0.1s~3600.0s | ||

| DC Braking | DC braking when starting and stopping DC braking frequency: 0.0Hz~maximum frequency, braking time: 0.0s~36.0s; Braking current: 0.0%~100.0% | ||

| Jog Operation | Jog operation frequency: 0.0Hz~maximum frequency Jog ACC/DEC time: 0.1s~3600.0s | ||

| Simple PLC & Multi-Step Speed Operation | Max. 16 steps speed running via built-in PLC or control terminal. | ||

| Built-in Dual PID | Built-in PID control to easily realize the close loop control of the process parameters (such as pressure, temperature, flow, etc.) | ||

| Automatic Voltage Regulation | Keep output voltage constant automatically when input voltage fluctuates | ||

| I/O Terminals | Input Terminals | Programmable DI: 7 on-off inputs, 1 high-speed pulse input 2 programmable AI: AI1: voltage -10 ~ 10V A12: voltage 0 ~ 10V or current 0/4 ~ 20mA | |

| Output Terminals | 1 programmable open collector output: 1 analog output (open collector output or high-speed pulse output) 2 relay outputs 2 analog output: 0/4~20mA or 0~10V | ||

| Communication Terminal×2 | Offer RS485 communication interface, support MODBUS-RTU communication protocol | ||

Model Selection

KE300 Variable Frequency Drive Types and Technical Parameters

| Type | Matched Motor | Rated Input Current (A) | Rated Output Current (A) | |

| kW | HP | |||

| Single Phase 220V | ||||

| KE300-0R4G-S2 | 0.4 | 0.5 | 5.4 | 2.3 |

| KE300-0R7G-S2 | 0.75 | 1 | 8.2 | 4 |

| KE300-1R5G-S2 | 1.5 | 2 | 14 | 7 |

| KE300-2R2G-S2 | 2.2 | 3 | 23 | 9.6 |

| Three Phase 220V | ||||

| KE300-0R4G-T2 | 0.4 | 0.5 | 3.4 | 2.3 |

| KE300-0R7G-T2 | 0.75 | 1 | 5 | 4 |

| KE300-1R5G-T2 | 1.5 | 2 | 7.7 | 7 |

| KE300-2R2G-T2 | 2.2 | 3 | 10.5 | 9 |

| KE300-004G-T2 | 4.0 | 5 | 18 | 17 |

| KE300-5R5G-T2 | 5.5 | 7.5 | 26 | 25 |

| KE300-7R5G-T2 | 7.5 | 10 | 35 | 32 |

| KE300-011G-T2 | 11 | 15 | 46.5 | 45 |

| KE300-015G-T2 | 15 | 20 | 62.5 | 60 |

| KE300-018G-T2 | 18.5 | 25 | 76 | 75 |

| KE300-022G-T2 | 22 | 30 | 92 | 91 |

| KE300-030G-T2 | 30 | 40 | 113 | 112 |

| KE300-037G-T2 | 37 | 50 | 157 | 150 |

| KE300-045G-T2 | 45 | 60 | 180 | 176 |

| KE300-055G-T2 | 55 | 75 | 214 | 210 |

| KE300-075G-T2 | 75 | 100 | 307 | 304 |

| Three Phase 380V | ||||

| KE300-0R7G-T4 | 0.75 | 1 | 3.4 | 2.1 |

| KE300-1R5G-T4 | 1.5 | 2 | 5.0 | 3.8 |

| KE300-2R2G-T4 | 2.2 | 3 | 6.8 | 6.0 |

| KE300-004G/5R5P-T4 | 4.0/5.5 | 5/7.5 | 10/15 | 9/13 |

| KE300-5R5G/7R5P-T4 | 5.5/7.5 | 7.5/10 | 15/20 | 13/17 |

| KE300-7R5G/011P-T4 | 7.5/11 | 10/15 | 20/26 | 17/25 |

| KE300-011G/015P-T4 | 11/15 | 15/20 | 26/35 | 25/32 |

| KE300-015G/018P-T4 | 15/18.5 | 20/25 | 35/38 | 32/37 |

| KE300-018G/022P-T4 | 18.5/22 | 25/30 | 38/46 | 37/45 |

| KE300-022G/030P-T4 | 22/30 | 30/40 | 46/62 | 45/60 |

| KE300-030G/037P-T4 | 30/37 | 40/50 | 62/76 | 60/75 |

| KE300-037G/045P-T4 | 37/45 | 50/60 | 76/90 | 75/90 |

| KE300-045G/055P-T4 | 45/55 | 60/75 | 92/113 | 90/110 |

| KE300-055G/075P-T4 | 55/75 | 75/100 | 112/157 | 110/150 |

| KE300-075G/090P-T4 | 75/90 | 100/125 | 157/180 | 150/176 |

| KE300-090G/110P-T4 | 90/110 | 125/150 | 180/214 | 176/210 |

| KE300-110G/132P-T4 | 110/132 | 150/175 | 214/256 | 210/253 |

| KE300-132G/160P-T4 | 132/160 | 175/210 | 256/307 | 253/304 |

| KE300-160G/185P-T4 | 160/185 | 210/250 | 307/350 | 304/340 |

| KE300-185G/200P-T4 | 185/200 | 250/260 | 350/385 | 340/377 |

| KE300-200G/220P-T4 | 200/220 | 260/300 | 385/430 | 377/423 |

| KE300-220G/250P-T4 | 220/250 | 300/330 | 430/468 | 423/465 |

| KE300-250G/280P-T4 | 250/280 | 330/370 | 468/525 | 465/520 |

| KE300-280G/315P-T4 | 280/315 | 370/420 | 525/590 | 520/585 |

| KE300-315G/350P-T4 | 315/350 | 420/470 | 590/620 | 585/640 |

| KE300-350G-T4 | 350 | 470 | 665 | 650 |

| KE300-400G-T4 | 400 | 530 | 785 | 720 |

| KE300-450G-T4 | 450 | 600 | 880 | 820 |

| KE300-500G-T4 | 500 | 660 | 960 | 900 |

| KE300-560G-T4 | 560 | 750 | 1050 | 1000 |

| KE300-630G-T4 | 630 | 840 | 1130 | 1100 |

| Three Phase 660V | ||||

| KE300-015G-T6 | 15 | 20 | 21 | 19 |

| KE300-018G-T6 | 18 | 25 | 28 | 22 |

| KE300-022G-T6 | 22 | 30 | 35 | 28 |

| KE300-030G-T6 | 37 | 40 | 40 | 35 |

| KE300-037G-T6 | 37 | 50 | 47 | 45 |

| KE300-045G-T6 | 45 | 60 | 55 | 52 |

| KE300-055G-T6 | 55 | 75 | 65 | 63 |

| KE300-075G-T6 | 75 | 100 | 90 | 86 |

| KE300-090G-T6 | 90 | 105 | 100 | 98 |

| KE300-110G-T6 | 110 | 130 | 130 | 121 |

| KE300-132G-T6 | 132 | 175 | 170 | 150 |

| KE300-160G-T6 | 160 | 210 | 200 | 175 |

| KE300-185G-T6 | 185 | 250 | 210 | 195 |

| KE300-200G-T6 | 200 | 260 | 235 | 215 |

| KE300-220G-T6 | 220 | 300 | 257 | 245 |

| KE300-250G-T6 | 250 | 330 | 265 | 260 |

| KE300-280G-T6 | 280 | 370 | 305 | 300 |

| KE300-315G-T6 | 315 | 420 | 350 | 330 |

| KE300-350G-T6 | 350 | 470 | 382 | 374 |

| KE300-400G-T6 | 400 | 530 | 435 | 410 |

| KE300-450G-T6 | 450 | 600 | 490 | 465 |

| KE300-500G-T6 | 500 | 660 | 595 | 550 |

| KE300-560G-T6 | 560 | 745 | 610 | 590 |

| KE300-630G-T6 | 630 | 840 | 700 | 680 |

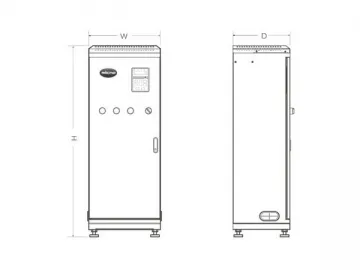

Overall Dimensions

KE300 Frequency Inverter Overall Dimensions and Installation Hole Dimensions

0.75~5.5kW

7.5~30k

37~200kW (including standard machine with power ranging from 90kW to 200 kW)

| Power Range | Overall Dimensions (mm) | Installation Dimensions (mm) | Installation Hole Diameter (mm) | ||||

| W | H1 | H2 | D | A | B | ||

| 0.75~2.2kW | 110 | 185 | 153 | 98 | 174 | M4 | |

| 4~ 5.5kW | 135 | 240 | 173 | 122.6 | 229 | M4 | |

| 7.5~15kW | 200 | 330 | 300 | 188.8 | 90 | 317 | M4 |

| 18.5~30kW | 255 | 440 | 403 | 229 | 140 | 423.6 | M5 |

| 37~45kW | 280 | 570 | 521 | 300 | 190 | 552 | M6 |

| 55~75kW | 320 | 600 | 552 | 330 | 230 | 582 | M8 |

| 90~110kW (without base) | 320 | 715 | 662 | 356 | 230 | 695.5 | M8 |

| 90~110kW (with base) | 320 | 992 | 962 | 356 | |||

| 132~200kW (without base) | 480 | 790 | 725 | 385 | 360 | 768 | M10 |

| 132~200kW (with base) | 480 | 1165 | 1125 | 385 | |||

Note: Standard variable speed drives with power ranging from 90kW to 200 kW have no base.

Applications

With high performance, KE300 variable frequency drive is widely used in a variety of occasions.

Various Draught Fans and Water Pumps

Washing Industry

Machine Equipment

Woodworking Equipment

Simple Lifting Appliances

Air Compressor, Centrifugal Machine and Ceramic Machinery

Other Low-End Application Occasions

Links:https://www.globefindpro.com/products/77721.html

-

Windscreen Washer Motor

Windscreen Washer Motor

-

Frequency Inverter (Vector Control Variable Frequency Drive)

Frequency Inverter (Vector Control Variable Frequency Drive)

-

35mm PM Stepper Motor

35mm PM Stepper Motor

-

Wiper Linkage

Wiper Linkage

-

Frequency Inverter (Energy Savings with Variable Speed Drive)

Frequency Inverter (Energy Savings with Variable Speed Drive)

-

Window Regulator

Window Regulator

-

Frequency Inverter (Open Loop Small Size Inverter)

Frequency Inverter (Open Loop Small Size Inverter)

-

78-B Series Gravure Printing Ink for PVC

78-B Series Gravure Printing Ink for PVC

-

Rear Wiper Motor

Rear Wiper Motor

-

8 Series Resin-Free Pigment Paste for Coloring Water-Based Paint

8 Series Resin-Free Pigment Paste for Coloring Water-Based Paint

-

Eco-Friendly Water-based Pigment Paste

Eco-Friendly Water-based Pigment Paste

-

QY660L RH750 Tire Changer

QY660L RH750 Tire Changer