5ton/day Cube Ice Machine

Working Conditions for 5ton/day Cube Ice Machine

| 1.Maximum ambient temperature | 40°C |

| 2.Relative humidity | 85% |

| 3.Supply water temperature | 16°C |

| 4.Power supply | 380V/3Phase/50Hz |

| 5.Refrigerant | R22 |

| 6.Compressor type | Semi-hermetic compressor |

| 7.Cooling system | Water cooled condenser |

Performance Parameters of Commercial Ice Cube Equipment

| No. | Item | Parameters | ||

| 1 | Name | Cube ice machine | ||

| 2 | Model | |||

| 3 | Quantity | 1 set | ||

| 4 | Daily output | 5ton/day | ||

| 5 | Weight | 1500kg | ||

| 6 | Dimension | Cube ice machine | Machine: 2890mm×1780mm×1840mm Cooling tower: Diameter1650mm, Height: 1775mm (The cooling tower is usually installed externally.) | |

| Cube ice | 22mm×22mm×22mm or 29mm×29mm×22mm | |||

| 7 | Noise | 55dB | ||

| 8 | Refrigerant | R22 | ||

| 9 | Evaporating temperature | -12°C | ||

| 10 | Condensing temperature | 40°C | ||

| 11 | Input water temperature | 16°C | ||

| 12 | Ambient temperature | 40°C | ||

| 13 | Compressor | Type | Semi-hermetic compressor | |

| Brand name | Bitzer | |||

| Quantity | 1 | |||

| Model No. | 6H-25.2 | |||

| Cooling capacity | 45.85kW | |||

| Power | 18.84kW | |||

| 14 | Power of cooling tower motor | 0.15kW | ||

| 15 | Power of cooling water pump | 2.2kW | ||

| 16 | Power of circulating water pump | 0.55kW | ||

| 17 | Evaporator | Type | Cube type | |

| Quantity | 18 pieces | |||

| 18 | Control system | PLC micro-computer control | ||

| 19 | Cube ice weight density | 500~550kg/m3 | ||

| 20 | Power consumption | 80~85kW.h/ton | ||

Main Component Brand of Cube Ice Machine for Food Preservation

| Item | Name of Component | Brand Name | Country of Origin |

| 1 | Compressor | Bitzer | Germany |

| 2 | Evaporator | CBFI | China |

| 3 | Water-cooled condenser | CBFI | |

| 4 | Solenoid valve | Casta | Italy |

| 5 | Expansion valve | Danfoss | Denmark |

| 6 | PLC program control | SIMENS | Germany |

| 7 | Electrical components | LG (LS) | South Korea |

| 8 | Oil meter High and lower pressure meter | Switzerland | Switzerland |

| 9 | Machine body material | Stainless steel 304 | |

Related names

Commercial ice cube equipment | Frozen foods processing equipment

Scan QR to Read

Links:https://www.globefindpro.com/products/77852.html

Links:https://www.globefindpro.com/products/77852.html

Recommended Products

-

1ton/day Automatic Ice Block Machine

1ton/day Automatic Ice Block Machine

-

Stainless Steel Handrail Bracket

Stainless Steel Handrail Bracket

-

MB Series 40ton/day Ice Block Machine

MB Series 40ton/day Ice Block Machine

-

Stainless Steel Base Plate

Stainless Steel Base Plate

-

MB Series 15ton/day Ice Block Machine

MB Series 15ton/day Ice Block Machine

-

6ton/day Flake Ice Machine

6ton/day Flake Ice Machine

-

Round Stainless Steel Tube

Round Stainless Steel Tube

-

Stainless Steel Rail Support

Stainless Steel Rail Support

-

5ton/day Automatic Ice Block Machine

5ton/day Automatic Ice Block Machine

-

MB Series 30ton/day Ice Block Machine

MB Series 30ton/day Ice Block Machine

-

Oval Slotted Stainless Steel Tube

Oval Slotted Stainless Steel Tube

-

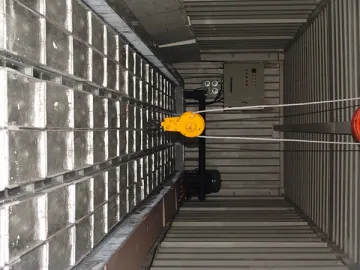

8ton/day Containerized Ice Block Machine

8ton/day Containerized Ice Block Machine