Crane Cabin

Applications

Our crane cabin is a kind of crane parts that can be adapted to special working conditions as high or low temperatures and dust hazards. It is a good choice for workshops, warehouses, stock grounds, freight yards, power stations, ports, shipyards, etc, which are under such special conditions.

Technical Features

1. The frame is welded with high quality profiles. The whole control room is covered by cold rolled steel plates processed by CNC machine tools. Inside the frame, the lining material for fire protection, heat insulation and sound insulation goes before the interior decoration.

2. The interior decoration is finished with middle density fiberboard and aluminum composite panel, or with steel sheets riveted together. The static load capacity of the top is above 2.5kN/m2.

3. The crane cabin window usually adopts 5mm thick toughened or laminated safety glass with a transmittance above 80%. The glass is fixed by rubber strips. The window frame is made of aluminum alloy or PVC profiles. The front windshield has safety rails to offer better security for the operator.

4. The floor adopts removable 4mm thick steel plate. The rubber carpet is anti-skid and shows good insulation. Control wires can be tied up on a wire rack under the floor. The cable outlet is pretreated to be smooth for the cable. The floor of outdoor platform is galvanized grating plate with patterns.

5. It is painted with epoxy zinc-rich primers, epoxy MIO barrier paint, and polyurethane topcoat. The total film thickness is above 210um, which shows excellent rust-proof property.

6. Our cabin is usually equipped with a shielded fluorescent lamp, lamp switches and a spare power socket. The front windshield has a wiper and a sprinkler. The ambient temperature should be -25 ℃ to 40℃.

Links:https://www.globefindpro.com/products/78199.html

-

Electric Wire Rope Hoist

Electric Wire Rope Hoist

-

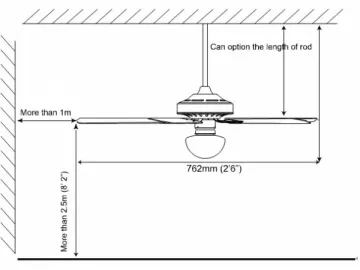

30" Ceiling Fan

30" Ceiling Fan

-

Jib Crane

Jib Crane

-

Electric Chain Hoist

Electric Chain Hoist

-

CT32601 32 Inch 6 Plastic Blade Ceiling Fan

CT32601 32 Inch 6 Plastic Blade Ceiling Fan

-

Semi Gantry Crane

Semi Gantry Crane

-

CT52512 52 Inch 5 Wooden Blade Ceiling Fan

CT52512 52 Inch 5 Wooden Blade Ceiling Fan

-

CT52506 52 Inch 5 Rattan Blade Ceiling Fan

CT52506 52 Inch 5 Rattan Blade Ceiling Fan

-

Double Girder Overhead Crane

Double Girder Overhead Crane

-

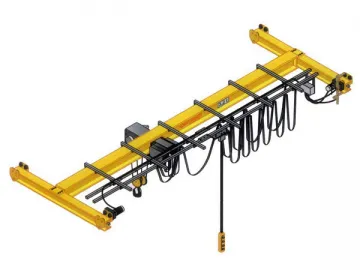

Single Girder Under Running Bridge Crane

Single Girder Under Running Bridge Crane

-

CT40601 40 Inch 6 Plastic Blade Ceiling Fan

CT40601 40 Inch 6 Plastic Blade Ceiling Fan

-

Frequency Converter for Crane

Frequency Converter for Crane