Butterfly Valve for Powder

The butterfly valve for powder is a kind of industrial product developed for powder and granule material. It is generally installed on the air pipeline or the exit of the hopper, silo and screw conveyor. Based on the material, our choke valve can be comprehensively sorted into three series, BVF-S, BVF-A and BV2F-F.

Introduction

BV.F-S Series

The high-pressure die-cast valve body is manufactured from aluminium alloy. The soft sealing structure, which is consisted of iron-cast interior lining panel covered with wear-resisting high polymer material and the abrasion resistant rubber seal ring, makes the butterfly valve for powder quite suitable for the application on various kinds of powdery and granular material, especially the material with higher abrasiveness.

① Stand---cast aluminium alloy

② Axle sleeve---nylon

③ Valve body---cast aluminium alloy

④ Disc---wear-resistant high polymer material

⑤ Seal ring---Nitrile-butadiene rubber

⑥ Axle sleeve---nylon

⑦ Valve body---cast aluminium alloy

BV.F-A Series

With portable high-pressure die-cast aluminium alloy valve body, the butterfly control valve is produced with #304/316 stainless steel disc. To meet the application in different environment, certain materials can be selected for the seal ring of the butterfly valve for powder, high temperature resistant silicone rubber, acid and alkali resistant rubber, EPDM, etc.

① Stand---cast aluminium alloy

② Axle sleeve---nylon

③ Valve body---cast aluminium alloy

④ Disc---#304/316 stainless steel

⑤ Seal ring--- rubber

⑥ Axle sleeve---nylon

⑦ Valve body---cast aluminium alloy

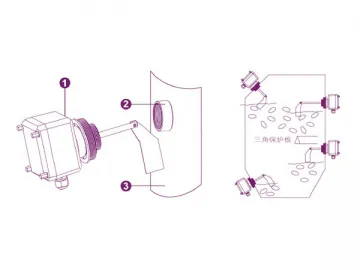

BV2F-F Series

The food-grade butterfly valve for powder is fully sealed with integrated rubber seal ring to completely avoid the contact between the material and the cast aluminium alloy valve body. Designed with #304/316 stainless steel disc, the product features easy and convenient maintenance and longer service life.

① Stand---cast aluminium alloy

② Axle sleeve---nylon

③ Valve body---cast aluminium alloy

④ Disc---#304/316 stainless steel

⑤ Seal ring---food grade rubber

⑥ Axle sleeve---nylon

⑦ Valve body---cast aluminium alloy

Classification Based on the Number of Flange

Based on the quantity of the flange, our product can be classified into BV1F-S single flanged butterfly valve with an extended adapter ring for the installation of the teleflex and BV2F-S double flanged butterfly valve with two identical flanged joints. Based on the actual demand, the lever drive and the air cylinder driving device are optional. The industrialized design, as well as the application of special composite materials, makes the BV.F butterfly valve quite popular due to the compact structure, abrasion resistant disc, long-life seal ring, simple installation and convenient maintenance.

Driving Device

According to different operating requirements and working conditions, we specially developed two kinds of driving device, lever drive and air cylinder drive.

| Butterfly Valve Model | BV-F1OOS | BV-F150S | BV-F200S | BV-F250S | BV-F300S | BV-F350S | BV-F400S |

| Lever Model | MD4 | MD4 | MD4 | MD4 | MD4 | MD2 | MD2 |

| Air Cylinder Model | PD100 | PD100 | PD100 | PD100 | PD100 | PD125 | PD1 |

Technical Parameters

1. BV1F-Series (Unit: mm)

| Model | ФA | ФB | ФC | ФD | E | F | G | ФH | ФN | ФP | ФR | S | T | U | V | Z | KG |

| BV1F100S | 95 | 180 | 220 | 105 | 250 | 117 | 35 | 22×19 | 14×4 | 20×4 | 220 | 40 | 80 | M12 | 50 | M10 | 5 |

| BV1F150S | 150 | 200 | 228 | 163 | 290 | 117 | 35 | 22×19 | 14×4 | 20×4 | 228 | 40 | 80 | M12 | 50 | M10 | 5.5 |

| BV1F200S | 200 | 250 | 278 | 213 | 340 | 117 | 35 | 22×19 | 14×4 | 20×4 | 278 | 40 | 80 | M12 | 50 | M10 | 7 |

| BV1F250S | 250 | 300 | 328 | 263 | 390 | 117 | 35 | 22×19 | 14×8 | 20×8 | 328 | 40 | 80 | M12 | 50 | M10 | 9 |

| BV1F300S | 300 | 350 | 378 | 313 | 440 | 117 | 35 | 22×19 | 14×8 | 20×16 | 378 | 40 | 80 | M12 | 50 | M10 | 11 |

| BV1F350S | 350 | 400 | 440 | 363 | 530 | 125 | 50 | 28×25 | 14×8 | 20×8 | 440 | 40 | 80 | M12 | -- | -- | 18 |

| BV1F400S | 400 | 470 | 530 | 413 | 580 | 125 | 50 | 28×25 | 14×8 | 20×16 | 530 | 40 | 80 | M12 | -- | -- | 23.5 |

2. BV2F-S Series Butterfly Valve for Powder (Unit: mm)

| Model | ФA | ФB | ФC | ФD | E | F | G | ФH | ФN | ФP | ФR | S | T | U | V | Z | KG |

| BV2F100S | 95 | 180 | 220 | -- | 250 | 77 | 35 | 22×19 | 14×4 | 20×4 | 220 | -- | 80 | M12 | 50 | M10 | 4 |

| BV2F150S | 150 | 200 | 228 | -- | 290 | 77 | 35 | 22×19 | 14×4 | 20×4 | 228 | -- | 80 | M12 | 50 | M10 | 4 |

| BV2F200S | 200 | 250 | 278 | -- | 340 | 77 | 35 | 22×19 | 14×4 | 20×4 | 278 | -- | 80 | M12 | 50 | M10 | 6 |

| BV2F250S | 250 | 300 | 328 | -- | 390 | 77 | 35 | 22×19 | 14×8 | 20×8 | 328 | -- | 80 | M12 | 50 | M10 | 7 |

| BV2F300S | 300 | 350 | 378 | -- | 440 | 77 | 35 | 22×19 | 14×8 | 20×16 | 378 | -- | 80 | M12 | 50 | M10 | 9.5 |

| BV2F350S | 350 | 400 | 440 | -- | 530 | 85 | 50 | 28×25 | 14×8 | 20×8 | 440 | -- | 80 | M12 | -- | -- | 15.5 |

| BV2F400S | 400 | 470 | 530 | -- | 580 | 85 | 50 | 28×25 | 14×8 | 20×16 | 530 | -- | 80 | M12 | -- | -- | 21 |

Butterfly Valve Download

window.onload =function(){setItemByDivId('container','one|two|three|four|five|six|seven|eight','etw_link','color:#fff; background:#ff0000;','color:#fff;background:#004c92','setclass');}

Links:https://www.globefindpro.com/products/78413.html

-

Filter Accessories

Filter Accessories

-

ZLP630B Suspended Platform

ZLP630B Suspended Platform

-

Filter Cartridge, Filter Bag

Filter Cartridge, Filter Bag

-

Pressure Relief Valve

Pressure Relief Valve

-

Steel Suspended Platform

Steel Suspended Platform

-

Horizontal Bag Filling and Sealing Machine

Horizontal Bag Filling and Sealing Machine

-

Vibrant Silo Venting Filter

Vibrant Silo Venting Filter

-

Aeration Nozzle

Aeration Nozzle

-

Filter Cleaning System

Filter Cleaning System

-

Rotary Level Indicator

Rotary Level Indicator

-

GB Standard LPG Cylinder

GB Standard LPG Cylinder

-

Seamless Steel Gas Cylinder

Seamless Steel Gas Cylinder