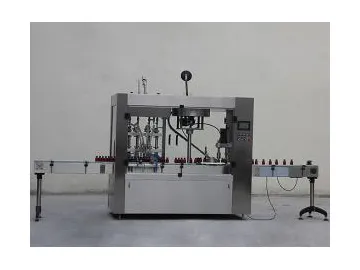

Automatic Filler and Capper (for Viscous Liquids), CBZ-4

The automatic filler and capper for low viscosity liquids combines filling and capping into one efficient machine. With precise and stable filling (only a ±1% error), the filling and capping machine can process a series of operations such as counting bottles, quantitative filling, and capping through a pressing, clamping, capping and conveying system. PLC and touch screen control offers accurate and easy adjustment to fit a variety of projects, and the filling machine can process glass and plastic round bottles for food, beverage, pharmaceutical, and cosmetic packaging. Different sealing rings are available to meet different standards.

Scan QR to Read

Links:https://www.globefindpro.com/products/7848.html

Links:https://www.globefindpro.com/products/7848.html

Recommended Products

-

Automatic Shrink Sleeve Labeler, TSB-150

Automatic Shrink Sleeve Labeler, TSB-150

-

SS035 Stainless Steel Hookah, 63cm Tall Middle Hookah

SS035 Stainless Steel Hookah, 63cm Tall Middle Hookah

-

Self-Adhesive Labeling Machine (for Round Bottle), TNZ-160

Self-Adhesive Labeling Machine (for Round Bottle), TNZ-160

-

SS0423 Stainless Steel Hookah, 54cm Tall Hookah

SS0423 Stainless Steel Hookah, 54cm Tall Hookah

-

Automatic Rotary Bottle Feeder, XZJ-200

Automatic Rotary Bottle Feeder, XZJ-200

-

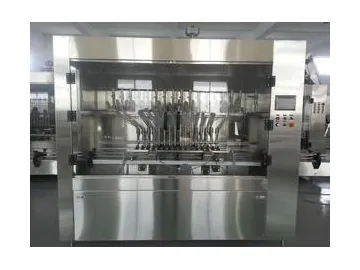

50-1000ml Liquid Filling Machine (for High Viscosity Liquid), ZSP-16A

50-1000ml Liquid Filling Machine (for High Viscosity Liquid), ZSP-16A

-

Automatic Inline Cap Tightening Machine, FXZ-160A

Automatic Inline Cap Tightening Machine, FXZ-160A

-

AL0406 Aluminum Hookah, 55cm Tall Hookah

AL0406 Aluminum Hookah, 55cm Tall Hookah

-

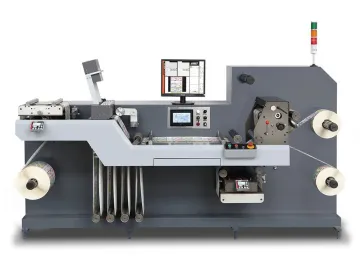

Auto Label Inspection Machine, ZB-420

Auto Label Inspection Machine, ZB-420

-

Automatic Screw Capping Machine (for 10-30L Flat Bottle/Drum), FX-1

Automatic Screw Capping Machine (for 10-30L Flat Bottle/Drum), FX-1

-

Automatic Filling and Capping Machine (for Watery Low Viscous Liquids), CZP-6/FX-1

Automatic Filling and Capping Machine (for Watery Low Viscous Liquids), CZP-6/FX-1

-

Shrink Tunnel, HX-100

Shrink Tunnel, HX-100