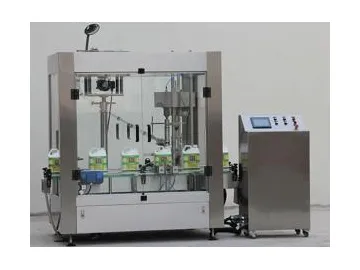

Automatic Rotary Screw Capping Machine, FX-8

This automatic rotary screw capping machine feeds in bottles, sorts caps, positions caps for bottling and dispenses capped bottles. The rotary screw capper is stable and reliable with accurate positioning that doesn't damage the caps. This machine has eight mechanical heads which dispatch caps quickly, synchronously, and efficiently. These heads can be configured to cap containers of different specifications, easily adjusted by a user-friendly PLC touch screen. With a high qualified rate, the bottle capper seals various sizes of glass and plastic bottles for the food and beverage, pharmaceutical, cosmetics, and chemical industries.

1. Cap catcher is made of rubber to prevent damage to caps.

2. Sensors automatically stop the machine when there are no bottles, the bottles are jammed, or there are no caps.

3. Stable and reliable operation.

4. User-friendly touch screen can adjust the height of the elevator and dimensions of the specifications.

The feeder ensures that all unused caps are drop ped back in the bucket.

Choose this capping machine if:

Caps with or without a protective lock ring are suitable

Configuration

| No. | Name | Brand | Origin | Quantity |

| 1 | Reducer motor | Ziguang | China | 1 |

| 2 | Power button | Schneider | France | 1 |

| 3 | Frequency inverter | Schneider | France | 2 |

| 4 | Sensor for bottles | OPTEX | Japan | 1 |

| 5 | Sensor for caps | Omron | Japan | 1 |

| 6 | Cap sort motor | Ziguang | China | 1 |

Suitable caps:

Links:https://www.globefindpro.com/products/7860.html

-

10-30L Automatic Drum Filler (with Weight Scale), ZCJ-6

10-30L Automatic Drum Filler (with Weight Scale), ZCJ-6

-

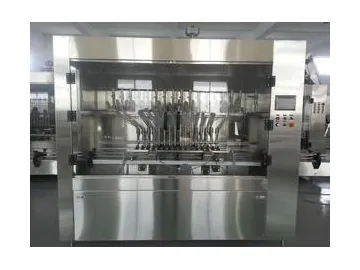

1000-5000ml Liquid Filling Machine (for High Viscosity Liquid), ZSP-8A

1000-5000ml Liquid Filling Machine (for High Viscosity Liquid), ZSP-8A

-

Automatic Screw Capping Machine(for 1-5L Flat Bottle/Drum), FX-1

Automatic Screw Capping Machine(for 1-5L Flat Bottle/Drum), FX-1

-

Single-Head Automatic Screw Capper, FX-1A

Single-Head Automatic Screw Capper, FX-1A

-

Wet Glue Labeling Machine (for Round Bottle), TN-120A

Wet Glue Labeling Machine (for Round Bottle), TN-120A

-

Cap Elevator, SG-1

Cap Elevator, SG-1

-

50-1000ml Liquid Filling Machine (for Low-Viscosity Liquid), ZGP-16H

50-1000ml Liquid Filling Machine (for Low-Viscosity Liquid), ZGP-16H

-

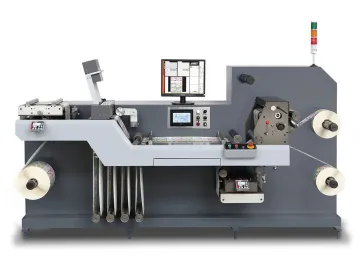

Auto Label Inspection Machine, ZB-520

Auto Label Inspection Machine, ZB-520

-

AL0404 Aluminum Hookah, 52cm Tall Hookah

AL0404 Aluminum Hookah, 52cm Tall Hookah

-

Silk Screen Printing Machine, WQ-320

Silk Screen Printing Machine, WQ-320

-

Automatic Bottle Unscrambler, LP-200

Automatic Bottle Unscrambler, LP-200

-

50-1000ml Liquid Filling Machine (for High Viscosity Liquid), ZSP-16A

50-1000ml Liquid Filling Machine (for High Viscosity Liquid), ZSP-16A