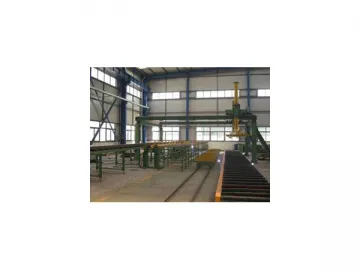

Roll Forming Machine

The roll forming machine is divided into two types, respectively capable of wall panel roll forming and corrugated panel roll forming.

Roll Former for Wall Panel

1. After processed by this machine, top and bottom steel plates are presented in male and female joint shape on both sides, providing convenience for subsequent installation and splicing.

2. Our roll forming machine is cassette-type structured, and thereby theoretical plate width can be obtained by adjusting distance between wall panels.

3. Each set of forming roller consists of top and bottom rollers which are demountable and interchangeable. Top rollers functions passively, and bottom rollers are motor driven via chain.

4. Interval between rollers is adjustable through regulating interval between bearings.

5. Working speed of this metal forming press is 0-8.8m/min. and can be regulated in stepless way, thus synchronized with the speed of entire sandwich panel production line.

6. Thanks to uniform hard chrome plating on surface, service life of rollers is greatly extended.

Roll Former for Corrugated Panel

1. This roll forming machine adopts high-strength welded steel frame, and motor power is 5.5KW.

2. Shape, quantity and dimension of corrugation depend on specific requirements of customers.

3. Interval between top and bottom rollers is adjustable by means of regulating thread rod mounted on top bearing seat.

4. Our roll forming machine works at a speed of 0-8.8m/min. Stepless speed regulation is achievable to make speed synchronous with speed of sandwich panel production line.

5. To increase the life of rollers, we treat roller surface with hard chrome plating.

Links:https://www.globefindpro.com/products/78623.html

-

Rockwool (Mineral Wool), Glasswool Cutting and Feeding System

Rockwool (Mineral Wool), Glasswool Cutting and Feeding System

-

XQ89/3YC Hydraulic Power Tongs

XQ89/3YC Hydraulic Power Tongs

-

Stacker and Packing Machine

Stacker and Packing Machine

-

Caterpillar Laminating Machine

Caterpillar Laminating Machine

-

Cut-to-length Band Saw

Cut-to-length Band Saw

-

Caterpillar Laminating Machine

Caterpillar Laminating Machine

-

Samsung EB425161LU Battery

Samsung EB425161LU Battery

-

Roll Forming Machine

Roll Forming Machine

-

Replacement Battery for Portable Devices

Replacement Battery for Portable Devices

-

Cut-to-length Band Saw

Cut-to-length Band Saw

-

Samsung EB575152VU/VA Battery

Samsung EB575152VU/VA Battery

-

Samsung B500BE Battery

Samsung B500BE Battery