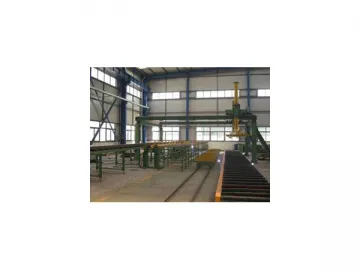

Caterpillar Laminating Machine

Overall Description

In light of years of machinery design experience and actual operation feedback, we successfully develop the caterpillar laminating machine. Its main body is connected by link plate of 1320mm wide, and main body length is 30m. Other lengths are also available. This building material production equipment is capable of top caterpillar band lifting via hydraulic cylinder and guide mechanisms.

Structural Features

1. The frame of this laminating machine is made of superior thick profile steel via welding, featured by high strength and less deformation. One-piece welded link plate is processed by CNC lathe, coming with high strength and flatness.

2. Link plate bearings adopt rolling friction transmission, and thereby tension of caterpillar band can be regulated via driven shaft.

3. Top and bottom caterpillar bands of our caterpillar laminating machine are designed with 40-200mm interval and guide mechanisms at both sides.

4. Nylon stop blocks can be adjusted according to different steel plate widths, and adjustable interval ranges from 600mm to 1200mm.

5. The sandwich panel laminator makes use of spiral gear reducer and frequency-variable synchronous motor for synchronized drive, thus realizing synchronized control for top link plate operation.

6. Our caterpillar laminating machine operates at a speed of 0-8.8m/min., available for stepless variable frequency speed regulation.

7. Stop blocks are used for sealing sandwich panel. Panel width and motion speed of stop blocks are controlled by three-phase motor and digitally displayed. Besides, dimension of nylon stop blocks are designed according to panel thickness required by customer.

8. PLC and control panel are utilized for operation control.

9. One set of electric heating system is attached, heating top and bottom caterpillar bands via hot air.

Links:https://www.globefindpro.com/products/78630.html

-

Laminating Machine

Laminating Machine

-

PU Foaming System

PU Foaming System

-

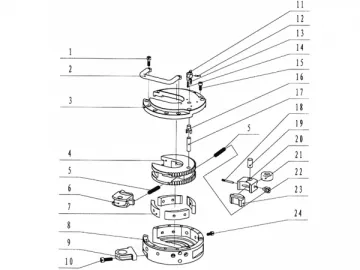

TQ340-35Y Casing Tongs

TQ340-35Y Casing Tongs

-

XQ28/1.8Y Sucker Rod Tongs

XQ28/1.8Y Sucker Rod Tongs

-

Hydraulic Power Pack

Hydraulic Power Pack

-

Uncoiler with Coil Feeding Car

Uncoiler with Coil Feeding Car

-

Cut-to-length Band Saw

Cut-to-length Band Saw

-

Caterpillar Laminating Machine

Caterpillar Laminating Machine

-

Stacker and Packing Machine

Stacker and Packing Machine

-

XQ89/3YC Hydraulic Power Tongs

XQ89/3YC Hydraulic Power Tongs

-

Rockwool (Mineral Wool), Glasswool Cutting and Feeding System

Rockwool (Mineral Wool), Glasswool Cutting and Feeding System

-

Roll Forming Machine

Roll Forming Machine