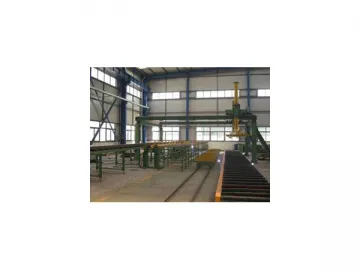

PU Foaming System

The PU foaming system fantastically functions by taking full advantage of high-pressure metering pump, temperature control system and automatic material supplying system. After fully mixed, two-component materials will be sprayed onto steel plate by means of mixing head in reciprocating motion.

Composition

Our PU foaming machine is mainly composed of following configurations:

1. Storage, conveying and pre-mixing equipment

2. High-pressure foaming unit

3. Electric control cabinet and process control unit

4. Cooling device

5. Spraying unit

Storage, Conveying and Pre-mixing Equipment

This equipment adopted by our PU foaming system consists of following components:

1. Two 500L pressure vessels with jacket layer, used for isocyanate and polyol storage

2. One electric stirrer for stirring polyol

3. One electric stirrer for stirring isocyanate

4. Flow transducer and operation panel

5. Conduit coupling

High-pressure Foaming Unit

The high-pressure foaming unit of our PU foam equipment contains:

1. Flow transducer and operation panel

2. High-pressure foam machine and spraying head (2 sets)

Electric Control Cabinet and Process Control Unit

1. Power system for high-pressure foaming, PLC

2. Display screen for data supervision and display

3. Working voltage: 380V, 50Hz

4. Boosting voltage: 24Vcc-24vca

5. Total power: 70KW

6. Working pressure: 6/8 bar

7. Air consumption: 300NL/min.

Cooling Device

The cooling device in PU foaming system is an accessory device. It enables water cooling via a closed loop, thus regulating working temperature of PU foam machine.

Spraying Unit

Liquid raw materials are conveyed to mixing head via high-pressure rubber hose, and mixed in the mixing head. Then, they are sprayed onto steel plate in motion. The entire system is a closed loop, controlled by PLC.

Technical Parameters

The technical parameters of our PU foaming system are as follows:

1. Maximum pressure: 200 bar

2. Temperature of components: 20°C

3. Minimum MDI output: 240kg/h

4. Minimum output of polyol: 200kg/h

5. Maximum MDI output: 1200kg/h

6. Maximum output of polyol: 1020kg/h

7. Moving speed of mixing head: 80m/min.

8. Maximum width for transverse movement: 1500mm

9. Maximum width for longitudinal movement: 1300mm

10. Spraying distance of mixing head: 500mm

11. Adjustment range of mixing head height: 150mm

12. Installed power: 2KW

Links:https://www.globefindpro.com/products/78632.html

-

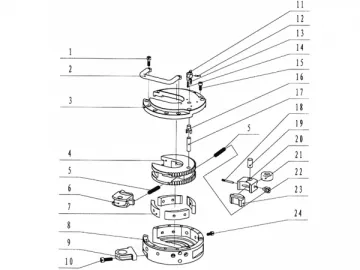

TQ340-35Y Casing Tongs

TQ340-35Y Casing Tongs

-

XQ28/1.8Y Sucker Rod Tongs

XQ28/1.8Y Sucker Rod Tongs

-

Hydraulic Power Pack

Hydraulic Power Pack

-

Uncoiler with Coil Feeding Car

Uncoiler with Coil Feeding Car

-

Roll Forming Machine

Roll Forming Machine

-

NJY/YT Computerized Torque Control System

NJY/YT Computerized Torque Control System

-

Laminating Machine

Laminating Machine

-

Caterpillar Laminating Machine

Caterpillar Laminating Machine

-

Cut-to-length Band Saw

Cut-to-length Band Saw

-

Caterpillar Laminating Machine

Caterpillar Laminating Machine

-

Stacker and Packing Machine

Stacker and Packing Machine

-

XQ89/3YC Hydraulic Power Tongs

XQ89/3YC Hydraulic Power Tongs