Stacker and Packing Machine

The stacker and packing machine are essential parts of PU and rock wool sandwich panel production line.

Stacker

A. Description

Our sandwich panel stacker adopts vacuum chuck for panel lifting, leaving no damage to panel. In addition to automatic panel stacking, it also comes with specialized rack to store unqualified panels. On the other hand, encoder for position detection is utilized to achieve neat and orderly stacking.

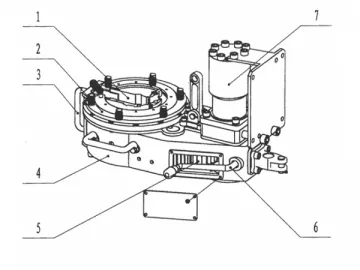

B. Components

Our stacker is mainly incorporated by:

1. Integrated framework

2. Travel mechanism

3. Lifting mechanism

4. Vacuum system and vacuum chuck

5. Transmission rack

6. Control and operation system

7. Automatic limit detection switch

8. Turnover device

C. Technical Parameters

| Min. panel length | 2m |

| Max. panel length | 12.5m |

| Single panel thickness | 40-250mm |

| Max. stacking height | 1.1m |

| Deviation in length direction | /-30mm |

| Deviation in width direction | /-10mm |

| Operation cycle | 60s |

Packing Machine

A. Description

By using this sandwich panel packer, sandwich panels are wrapped with film, and thereby they won’t be damaged during transportation and storage. Meanwhile, the film helps to resist humidity and dust pollution. For sandwich panels, the film during wrapping is in helical motion, and film replacement is manually operated, only needing about 30 seconds.

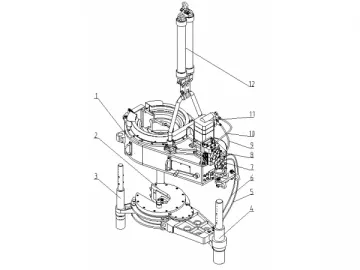

B. Components

Our packing machine is mainly composed of following parts:

1. Turnover device

2. Film unwinding stand

3. Automatic film wrapping device

4. Automatic film cutting device

5. Operation control system

6. Transmission rack

7. Automatic padding block device

8. Electrical control system

C. Technical Parameters

| Min. packing length | 3.5m |

| Max. packing length | 12.5m |

| Single panel thickness | 40-250mm |

| Max. stacking height | 1.1m |

| Max. width | 1250mm |

| Working speed | About 0-5m/min. |

| Overall dimension | 14m×2.7m×2.6m |

| Weight | 5T |

| Bore diameter of wrapping ring | 1828mm |

Links:https://www.globefindpro.com/products/78644.html

-

ZQ203-100Ⅱ Drill Pipe Tongs

ZQ203-100Ⅱ Drill Pipe Tongs

-

ZQ203-125Ⅱ Drill Pipe Tongs

ZQ203-125Ⅱ Drill Pipe Tongs

-

XQ28/2.6Y Sucker Rod Tongs

XQ28/2.6Y Sucker Rod Tongs

-

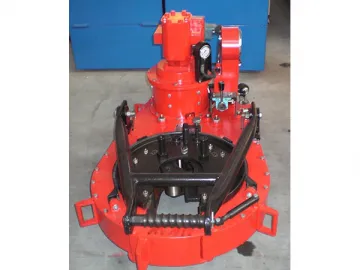

XQ140/12Y Hydraulic Power Tongs

XQ140/12Y Hydraulic Power Tongs

-

TQ340-35 Casing Tongs

TQ340-35 Casing Tongs

-

DQ140/20YB Hydraulic Power Tongs

DQ140/20YB Hydraulic Power Tongs

-

DQ178/40Y-TB Hydraulic Power Tongs

DQ178/40Y-TB Hydraulic Power Tongs

-

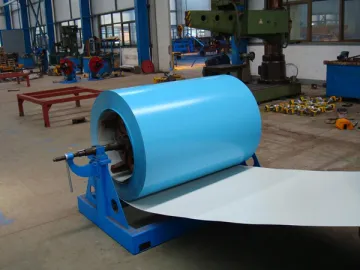

Uncoiler

Uncoiler

-

DQ197/40Y Hydraulic Power Tongs

DQ197/40Y Hydraulic Power Tongs

-

DQ197/40Y-TB Hydraulic Power Tongs

DQ197/40Y-TB Hydraulic Power Tongs

-

Cut-to-length Band Saw

Cut-to-length Band Saw

-

NJY/YT Computerized Torque Control System

NJY/YT Computerized Torque Control System