Heat Pump Sausage Dryer

The heat pump sausage dryer is a meat dryer that has three drying phases.

1. Constant Drying Process

This phase lasts for 5 to 6 hours. Within 2 hours after sausage has been placed in the drying room, the temperature speedily rises to 60 - 65℃. No moisture removal is needed. The constant drying process, also called preheating phase, is mainly for fermentation, which is beneficial for preventing meat from going bad. Some heating time later, adjust the temperature down to 45 - 50℃. The humidity should be controlled among 50% to 55%.

2. Slow Drying Process

The second process is designed for color development and contraction shaping. It lasts for 3 to 4 hours with the temperature controlled among 52 - 54℃ and humidity of around 45%. In this stage, the sausage changes color from light red to bright red. Casings for sausages start to shrink. You need to mind the occurrence of hard casing. Alternate cooling and heating can be used for better drying effect.

3. Rapid Drying Process

Main restriction factor is temperature. To strengthen the drying speed, temperature should be 60 - 62℃, while the drying time is controlled between 10 hours to 12 hours. 38% relative humidity is required. Humidity for final sausage drying is controlled below 17%.

Advantages

1. Our heat pump sausage dryer can effectively ensure the quality and properties of the dried materials.

2. In the drying process, temperature distribution is uniform. Humidity can be automatically controlled.

3. The drying process is safe and reliable, as the heat pump dryer won't cause any risk to humans.

4. Energy-effective as it is, the sausage drying machine is effectively decreased in operation cost.

5. It is an universal heat pump meat dryer. It has a high utilization rate while decreasing the investment cost.

Links:https://www.globefindpro.com/products/79021.html

-

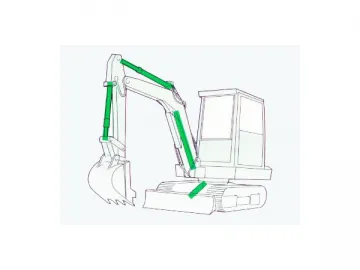

Excavator Hydraulic Cylinder

Excavator Hydraulic Cylinder

-

Lathe Hydraulic Cylinder

Lathe Hydraulic Cylinder

-

Microwave Liquid Heater

Microwave Liquid Heater

-

HSA-2,HSD-2 Digital Shore Durometer

HSA-2,HSD-2 Digital Shore Durometer

-

Single Action Hydraulic Cylinder

Single Action Hydraulic Cylinder

-

V-1000 Pocket Vibration Meter

V-1000 Pocket Vibration Meter

-

Microwave Puffing System

Microwave Puffing System

-

4001-0001 Digital Refractometer

4001-0001 Digital Refractometer

-

CT-2000 Coating Thickness Gauge with External Probe

CT-2000 Coating Thickness Gauge with External Probe

-

Street Washer Hydraulic Cylinder

Street Washer Hydraulic Cylinder

-

H-1000 Economical Portable Hardness Tester

H-1000 Economical Portable Hardness Tester

-

Piston Rod

Piston Rod