DHV-2101 Digital Vickers Hardness Tester

The DHV-2101 digital Vickers hardness tester makes use of large LCD to display measured data. Its operation interface is based on menu structure. The operator can select scale of hardness HV or HK on the operation panel. It supports the switch between various hardness numbers. The results can be automatically stored, processed or printed. Through the RS-232 interface, the hardness testing machine can be connected to a computer. With high digitization and automation, the hardness tester is capable of correcting value errors by means of software input.

Different from manual DHV-2101, the DHV-2102 belongs to digital hardness tester with automatic turret function. When measuring hardness, this non-destructive testing equipment supports the mutual switch between the indenter and objective lens. It is also provided with automatic positioning testing point function.

Technical Parameters| Model | DHV-2101/2102 |

| Test force | 10gf (0.098N) , 25gf (0.245N) , 50gf (0.49N) , 100gf (0.98N) , 200gf (1.96N) , 300gf (2.94N) , 500gf(4.9N) , 1kgf (9.8N) |

| Minimum test unit | 0.031µm |

| Data output | LCD displaying readings, built-in printer and RS-232 interface |

| Maximum height of specimen | 80mm |

| Distance between indenter and outer wall | 95mm |

| X-Y testing bench | Dimension: 100*100mm Maximum movement: 25*25mm |

| Ruler conversion | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Hardness testing range | 8~2900HV |

| Applying method of test force | Automatic (loading, dwelling, unloading) |

| Test microscope magnification | 400X (measuring), 100X (observing) |

| Duration time of test force | 0~60s |

| Power supply | AC220V 5%, 50-60Hz |

| Dimension | 405*290*480mm |

| Weight | About 25Kg |

Accessories

| Name | Quantity | Name | Quantity |

| Weight shaft | 1 | Weight | 6 |

| Cross testing bench | 1 | Sheet clamping unit | 1 |

| Flat clamping unit | 1 | Filament clamping unit | 1 |

| Screwdriver | 2 | Adjusting screw | 4 |

| Small gradienter | 1 | 10X test eyepiece | 1 |

Links:https://www.globefindpro.com/products/79033.html

-

H-3000 Portable Hardness Tester with Printer

H-3000 Portable Hardness Tester with Printer

-

F-2100 Digital Force Gauge

F-2100 Digital Force Gauge

-

Heat Pump Incense Dryer

Heat Pump Incense Dryer

-

HRRS-150 Dual-purpose Rockwell Hardness Tester

HRRS-150 Dual-purpose Rockwell Hardness Tester

-

V-2000 Digital Vibration Meter

V-2000 Digital Vibration Meter

-

Microwave Ceramic Sintering Furnace

Microwave Ceramic Sintering Furnace

-

Cylinder Tube

Cylinder Tube

-

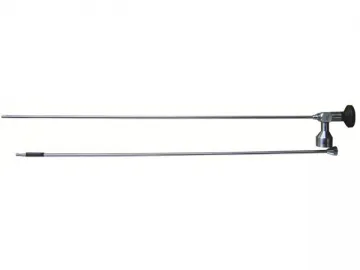

B-2000 Rigid Borescopes

B-2000 Rigid Borescopes

-

V-1000 Pocket Vibration Meter

V-1000 Pocket Vibration Meter

-

Single Action Hydraulic Cylinder

Single Action Hydraulic Cylinder

-

HSA-2,HSD-2 Digital Shore Durometer

HSA-2,HSD-2 Digital Shore Durometer

-

Microwave Liquid Heater

Microwave Liquid Heater